- Highlights

- Features

- Technical data

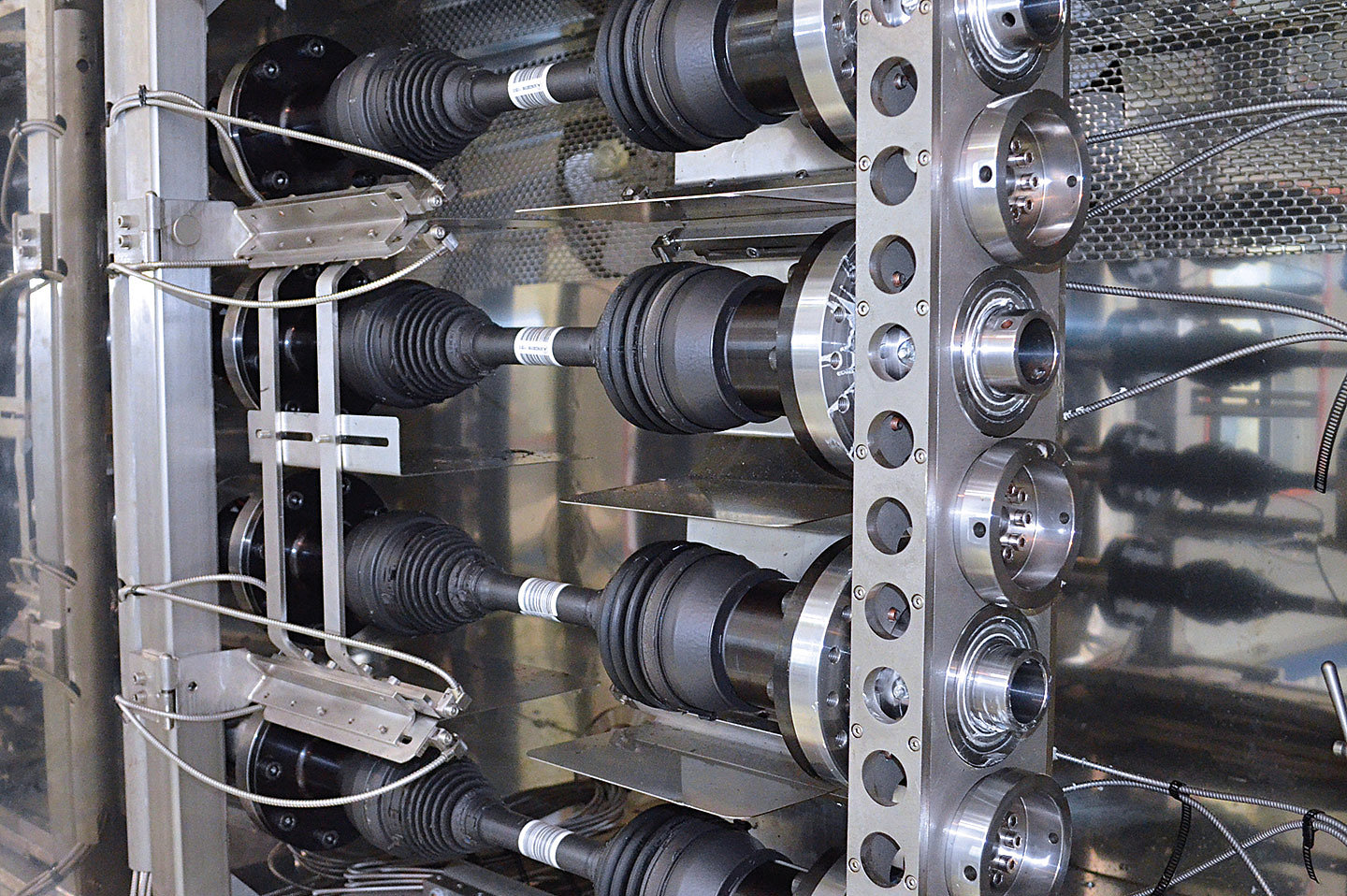

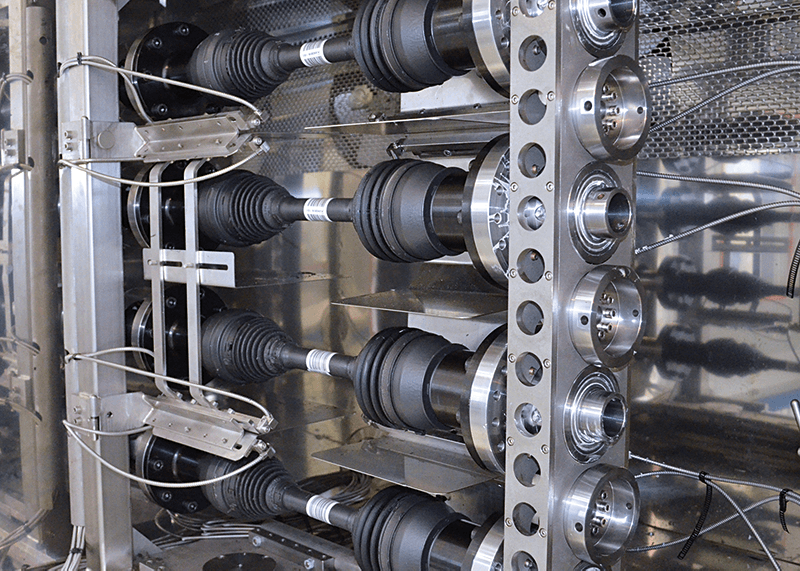

- Main dimensions: H = 2700 mm, W = 2000 mm, D = 2700 mm

- Test shaft speed 0 – 2500 rpm

- Test temperature range: -40 °C to +150 °C

- Number of test shafts: 4

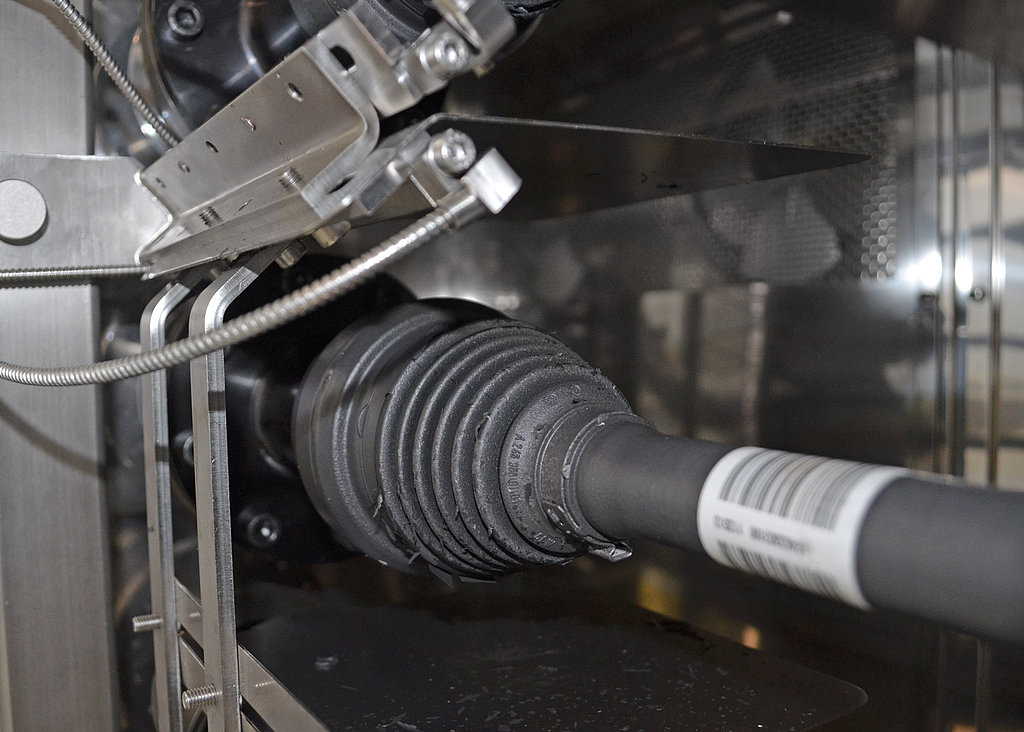

- Side shaft length: 250 to 630 mm between the joint centre points

- Pivot point clearance 40 to 150 mm from the flange face

- Overall shaft length: from flange to flange max. 800 mm

- Weight of the test stand: ~4000 kg

- Chamber dimensions: H = 950 mm, W = 1100 mm, D = 950 mm

- Temperature range: -40 °C to +150 °C

- Max. temperature fluctuations (temporal): ± 2 K

- Max. temperature distribution (spatial): ± 2 K

- Rate of temperature change: cooling: 2 K/min | heating: 2 K/min

- Temperature gradient: 2 K as per EN 60068-3-5**

- Connected load: 27 kW

- Weight of chamber: ~1100 kg

- Inspection glass: H = ~600 mm | W = ~500 mm

- Chamber pressure: Ambient pressure

** These values apply for an external air temperature of 25 °C

The NovoPS test stand software is a Windows-based solution that is programmed in-house and optimised for the respective test task. As the interface to the user, the uncomplicated user interface provides intuitive access to all functions of the test stand. Moreover, both the connection of the test stand to the customer's conveyor systems as well as its integration into the existing network environment is taken into account. This enables the data acquired to be processed and evaluated independently of the test stand.

Data recording

- Analogue data

- Digital data (SSI etc.)

- CAN data (with synchronisation to analogue data)

Data storage

- Data export as a text file (.csv), DIADEM file

- Database connection ODBC, MS Access, SQL Server

Creating and editing test programs

- Generation or import of test program data records

- Editing program sequences

- Evaluation within the sequences

- Free adaptation of test sequences

- On-line graphic of recorded data