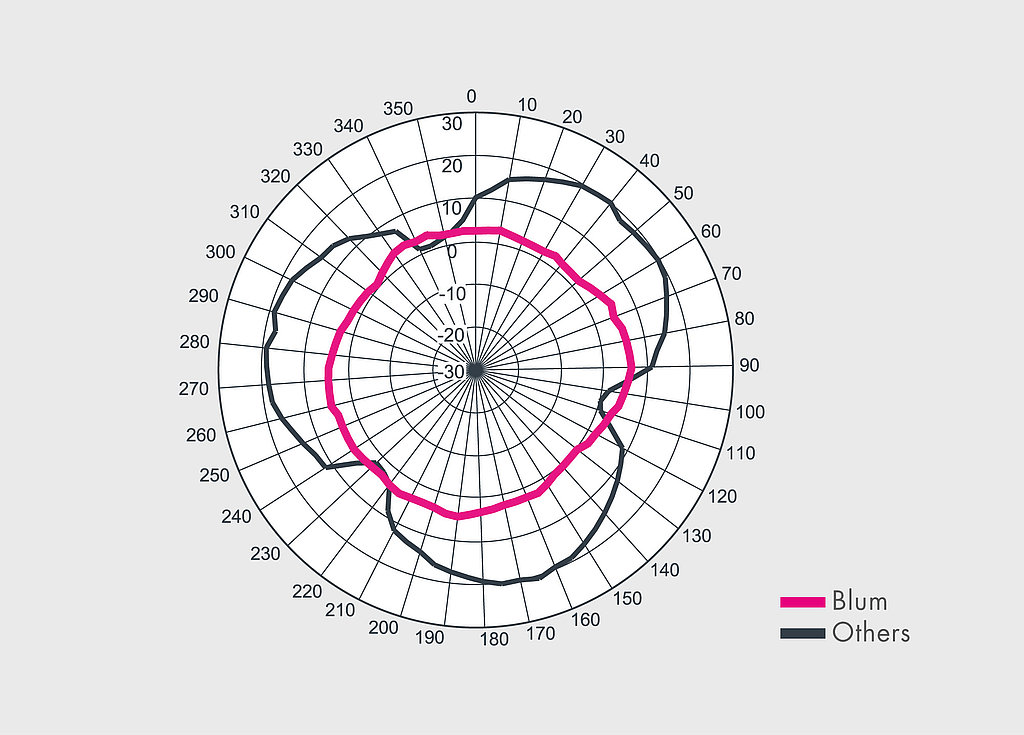

Economic solutions for tool setting in length and radius as well as for tool breakage monitoring. Precise and reliable measurements thanks to cutting-edge measuring mechanism technology with optoelectronic switch signal generation.

ZX-Speed Series – Reliable tool measuring probes for a wide variety of machines

- Highlights

- Applications

- Features

- Accessories

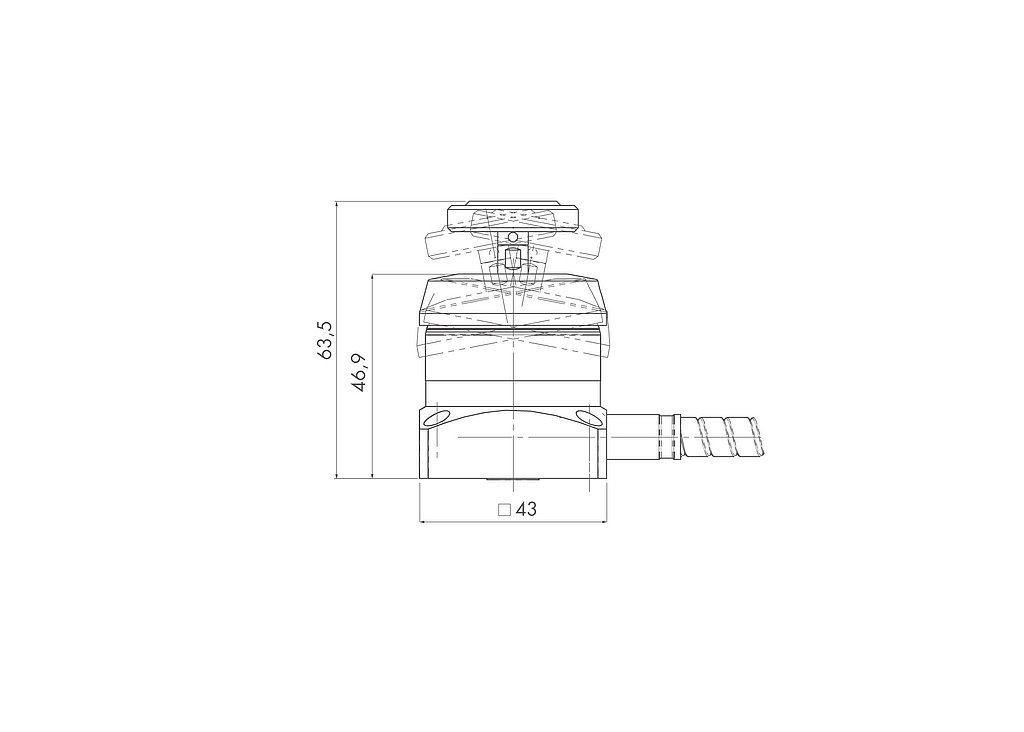

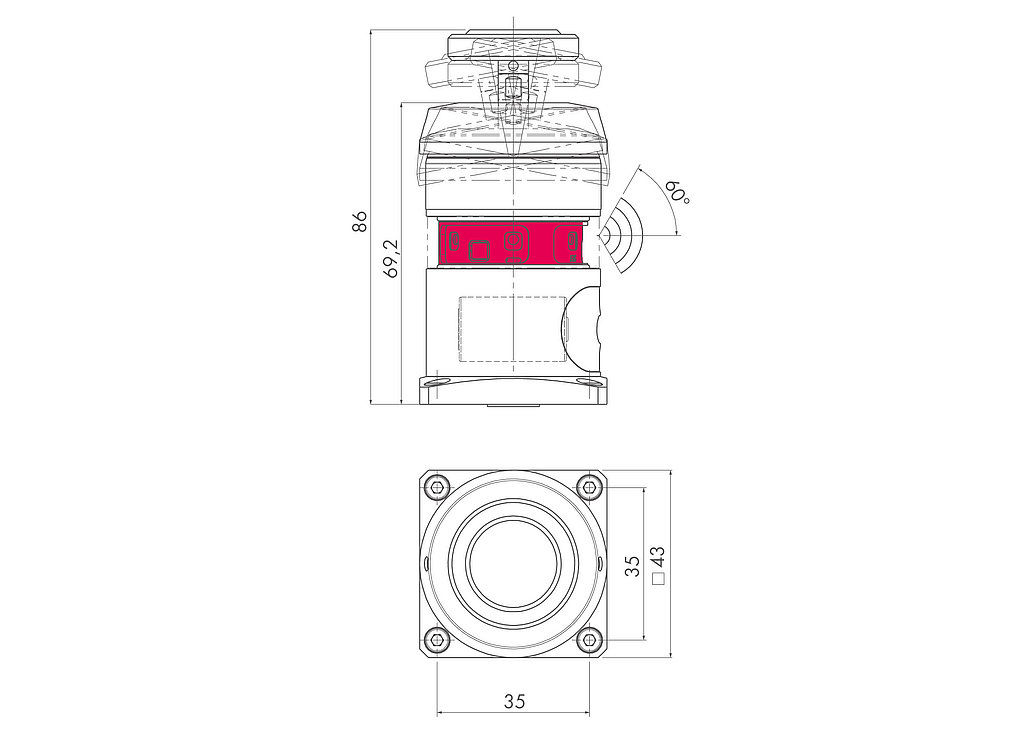

- ZX-Speed: Hardwired

- ZX-Speed IR: Infrared Transmission

- ZX-Speed RC: BRC Radio Technology

- DUO-Mode: Sequential use of 2 infrared measuring systems with one receiver

- Sequential use of up to 6 radio measuring systems with one receiver

- TWIN mode: Simultaneous use of 2 radio measuring systems on one machine

- Very long battery life

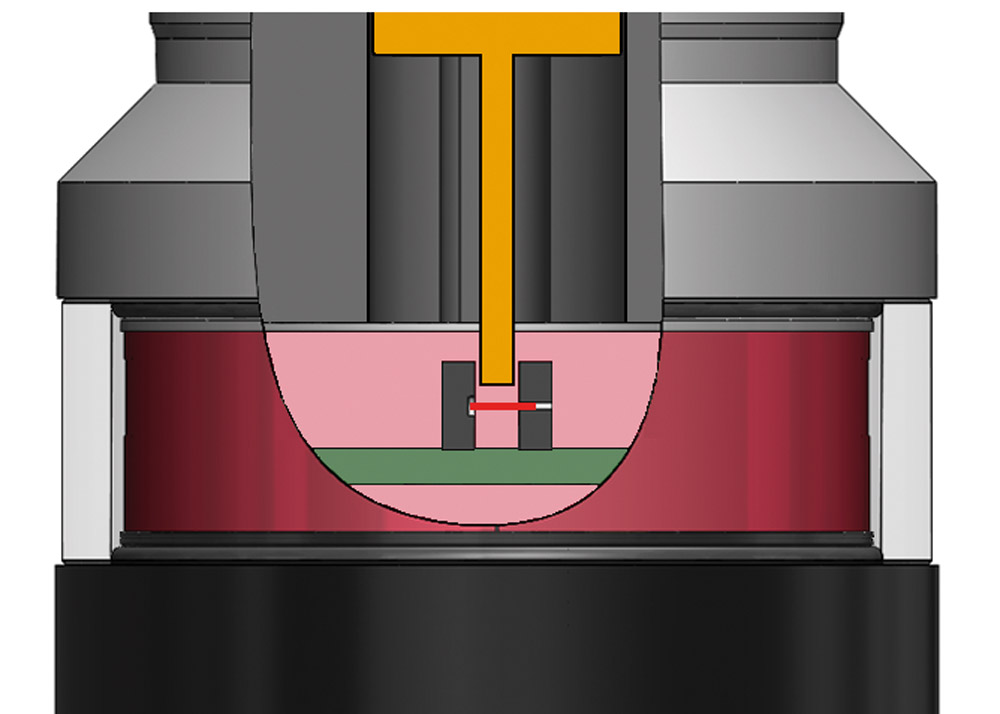

3D tool measuring probes by BLUM can be used for the most varied measurement and monitoring tasks in CNC machining centres.

Breakage detection of centric tools such as drills, mills, engraving tools, taps and reamers.

Automatic setting and wear monitoring of tools by quick and precise length measurement.

Automatic recording of tool diameter and wear by quick and precise radius measurement.

Compensation of tool wear using measurements between the machining steps. The wear value is stored as an additive correction value in the tool offset memory.

Compensation of the temperature-dependent thermal behaviour of machining centres.

Reliable and fast measurements in coolant thanks to modern measuring mechanism and robust design.

Perfectly suitable for mass production under the harshest conditions.