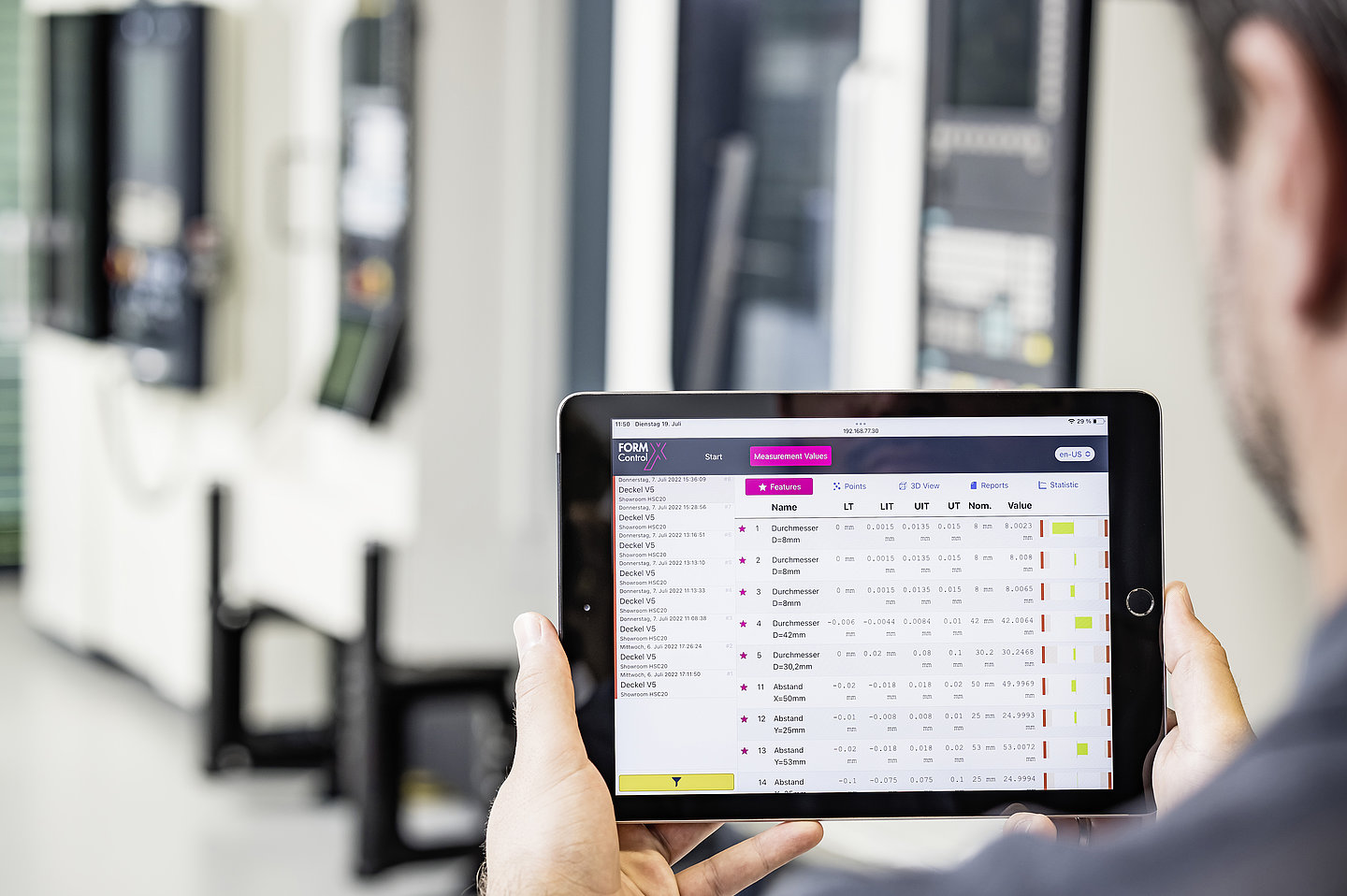

The highlight of this year’s presentation will be the FormControl X measuring and automation software, which will be shown interacting with a cobot at the BLUM booth. This is a clever solution for machining centres for machine-integrated quality control of workpieces in series production. The software enables automated monitoring of machining processes in line with the principle of statistical process control (SPC). The process is managed based on the recorded measured values and previously defined warning and control limits. To make sure that this also works perfectly in unmanned operation and in cooperation with robot solutions, FormControl X offers a clever approach with its alignment function. This feature detects the current workpiece position and alignment right after clamping and automatically adjusts the reference points of the machining program to the actual position of the workpiece. This also makes reliable automated machining of parts with small allowances possible. FormControl X also prepares the recorded data in graphic form. It can then be visualised and evaluated by the user using the web browsers of any end devices. FormControl X accelerates manufacturing processes and makes them more transparent, and the quality and manufacturing costs of the finished workpieces are optimised.

The second software solution that BLUM will present at the EMO is the latest version of the LC-VISION measuring and visualisation software. The application, which was developed specially for the laser measurement systems from BLUM, has been adapted even more closely to the needs of users and its usability has also been improved. For instance, the free standard scope has been expanded to include the “ToolControl” and “Stability” functions. ToolControl is an intuitive application which even users without NC programming knowledge can use to quickly and easily generate measuring sequences for the most common measuring tasks. The user can visualise measuring sequences for tool length and radius, including the tool-specific wear limits, directly on the control screen and take appropriate action. The stability function is used to determine the thermally stable spindle state for high-precision machining, to name just one example. If a machine is in the warm-up phase, the spindle elongation is measured at speed and the length value in the tool memory is updated after the thermally stable state is reached. For ambitious measuring tasks, there are also optional technology cycles available such as “ToolControl Advanced” or “SpindleControl”.

“The third highlight of the trade fair, the new TWIN technology, makes it possible to simultaneously operate two BLUM tool or workpiece probes with only one radio receiver. This technology is mainly used in dual-spindle machines, whereby a cycle time reduction of up to 50% can be achieved due to the omission of a second probing movement. The BRC technology used ensures secure transmission, and no line of sight to the receiver is required,” Weiland concludes.