- Highlights

- Applications

- Features

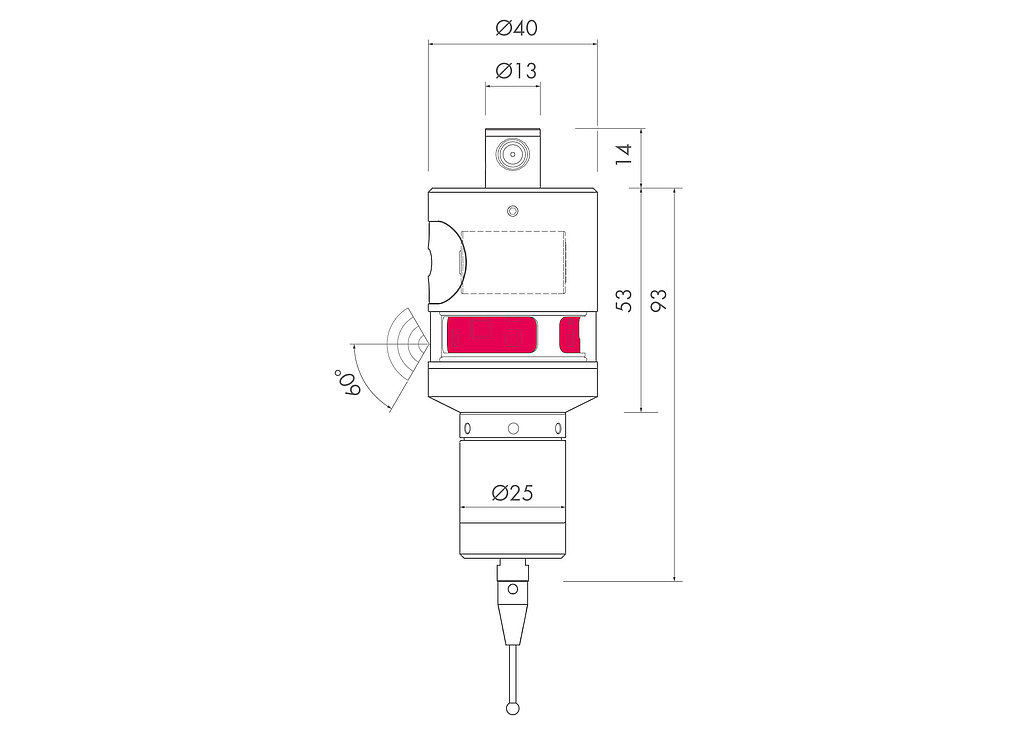

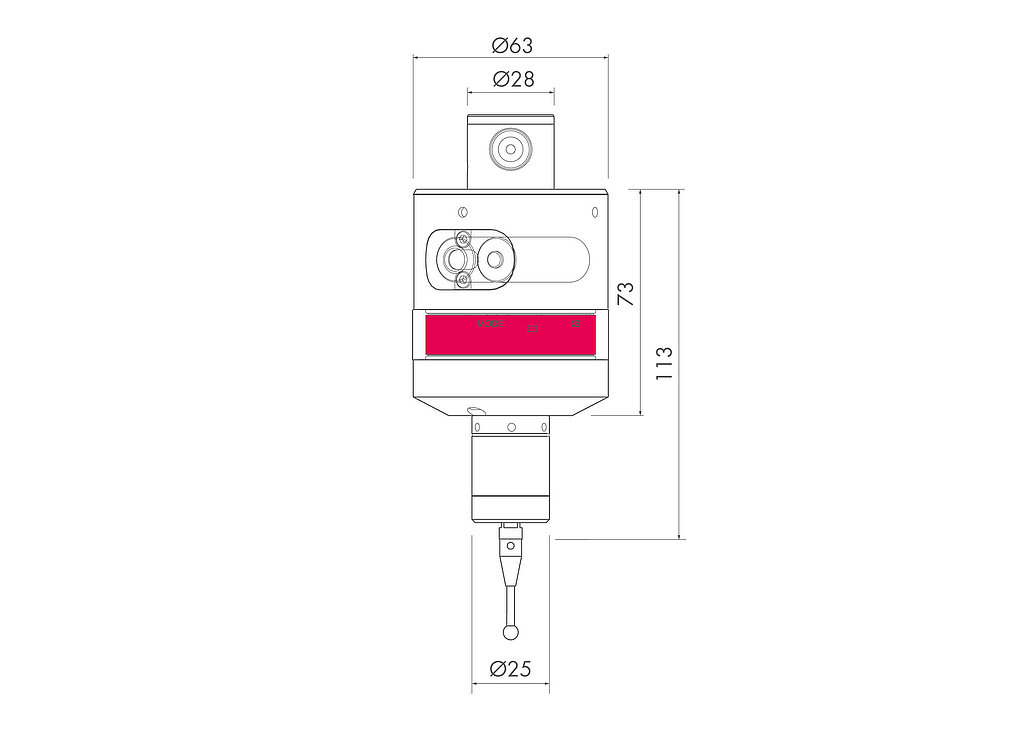

- Variants

BLUM 3D CNC Touch Probes

3D CNC touch probes by BLUM can be used for the most varied measurement and monitoring tasks in CNC machining centres.

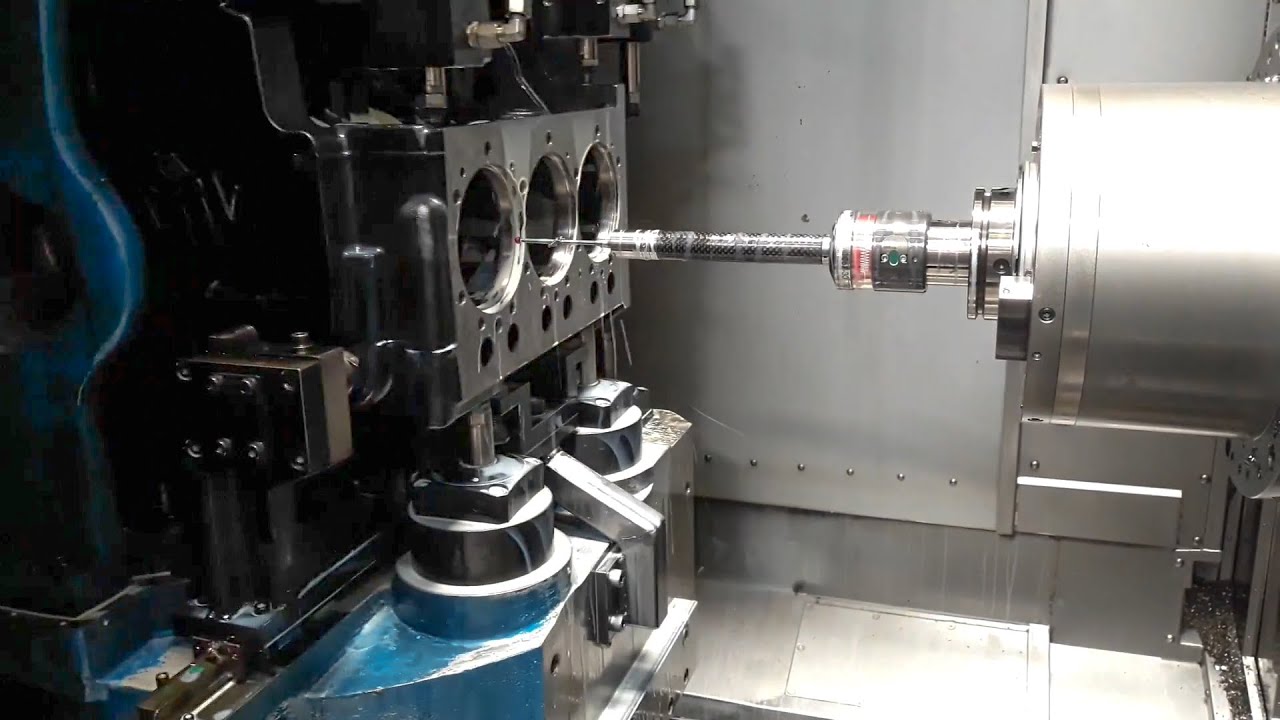

Fast determination of current workpiece position (workpiece zero point) prior to machining or after resetting using digital (switching) measurement.

Digital (switching) measurement of distances, single points, angles, inside and outside diameters, inside and outside widths on a manufactured workpiece.

Fast measurement of inside widths, outside widths and recesses using pulling/pushing measurements in Z+/Z- with the help of cranked styli.

The measuring system’s modular design allows for customer-specific adaptation to special measurement tasks. BLUM offers a comprehensive range of accessories such as extensions and elbows for this purpose.

Inspection of the manufactured workpieces for machining errors and adherence to manufacturing tolerance by means of control measurements prior to clamping.

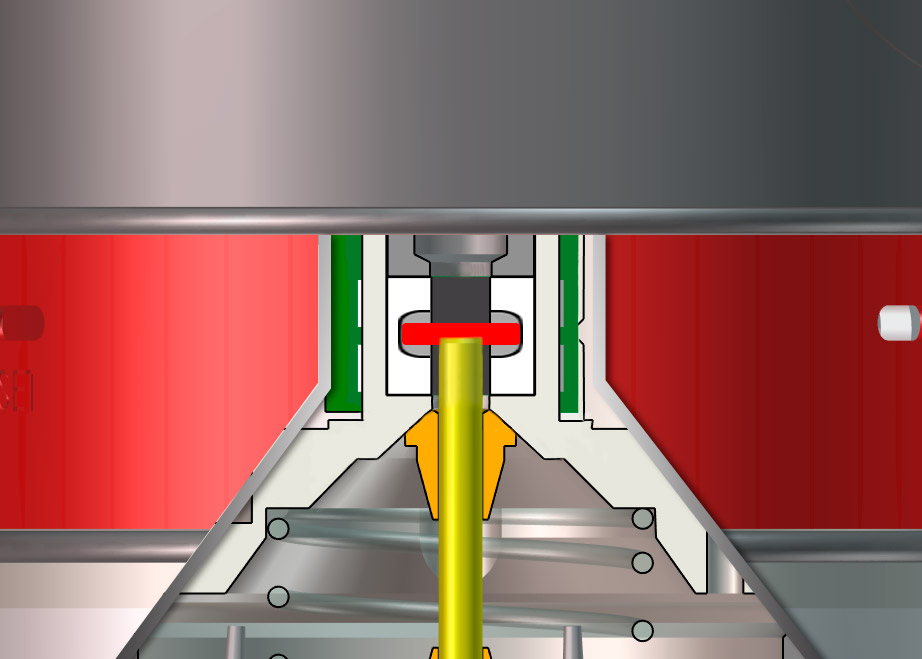

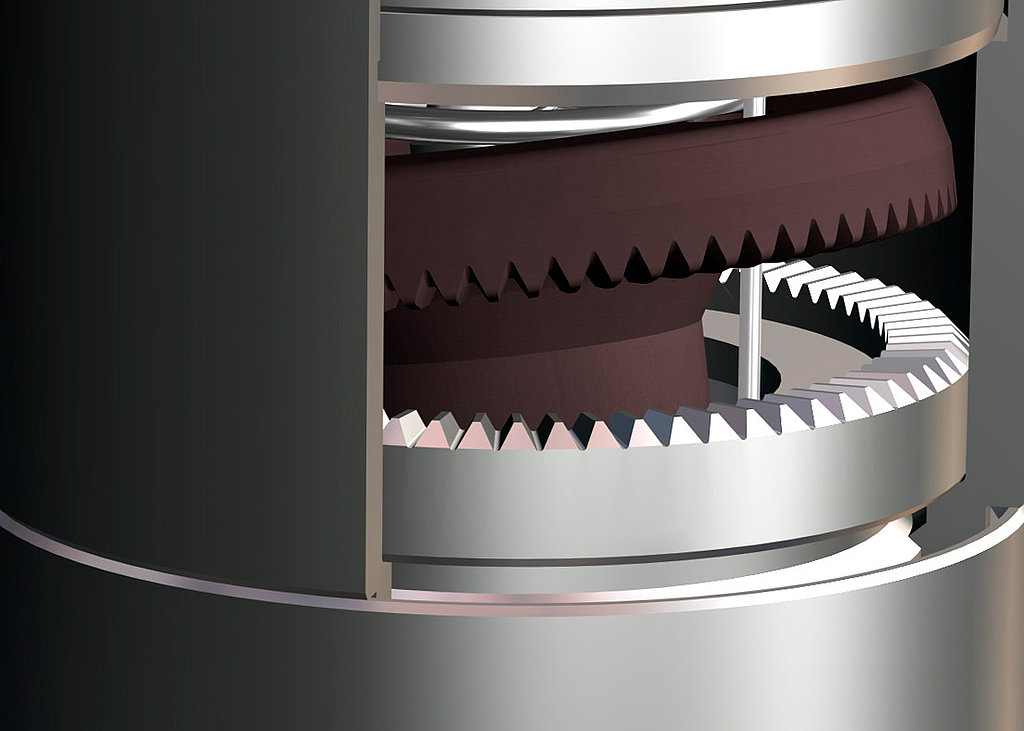

Unlike conventional touch probes, the unique shark360 measuring mechanism also allows for measurements in which a torsional force acts on the measuring mechanism.

Determination of parameters for adaptive machining and process control between and after the machining steps.

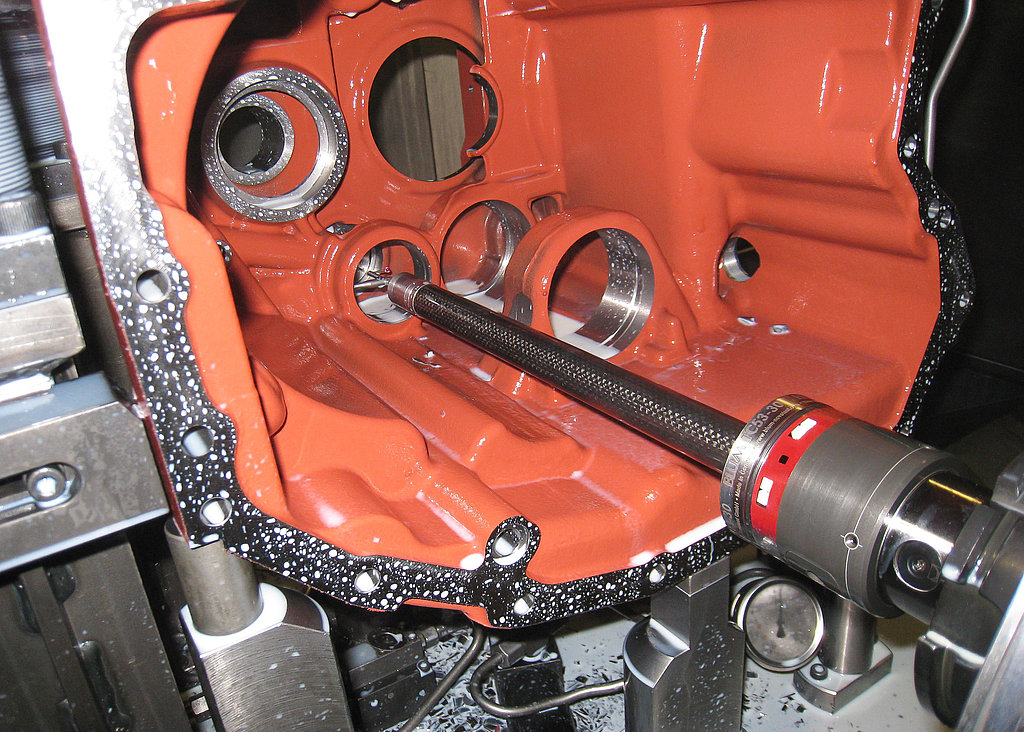

Reliable and fast measurements in the coolant thanks to modern measuring mechanism with increased measuring force.

Perfectly suitable for mass production under the harshest conditions thanks to robust design and protection class IP68.

Tool wear is compensated for by taking measurements on the workpiece and comparing these with the nominal dimension.

Compensation of the temperature-dependent thermal behaviour of machining centres.