- Highlights

- Features

- Technical data

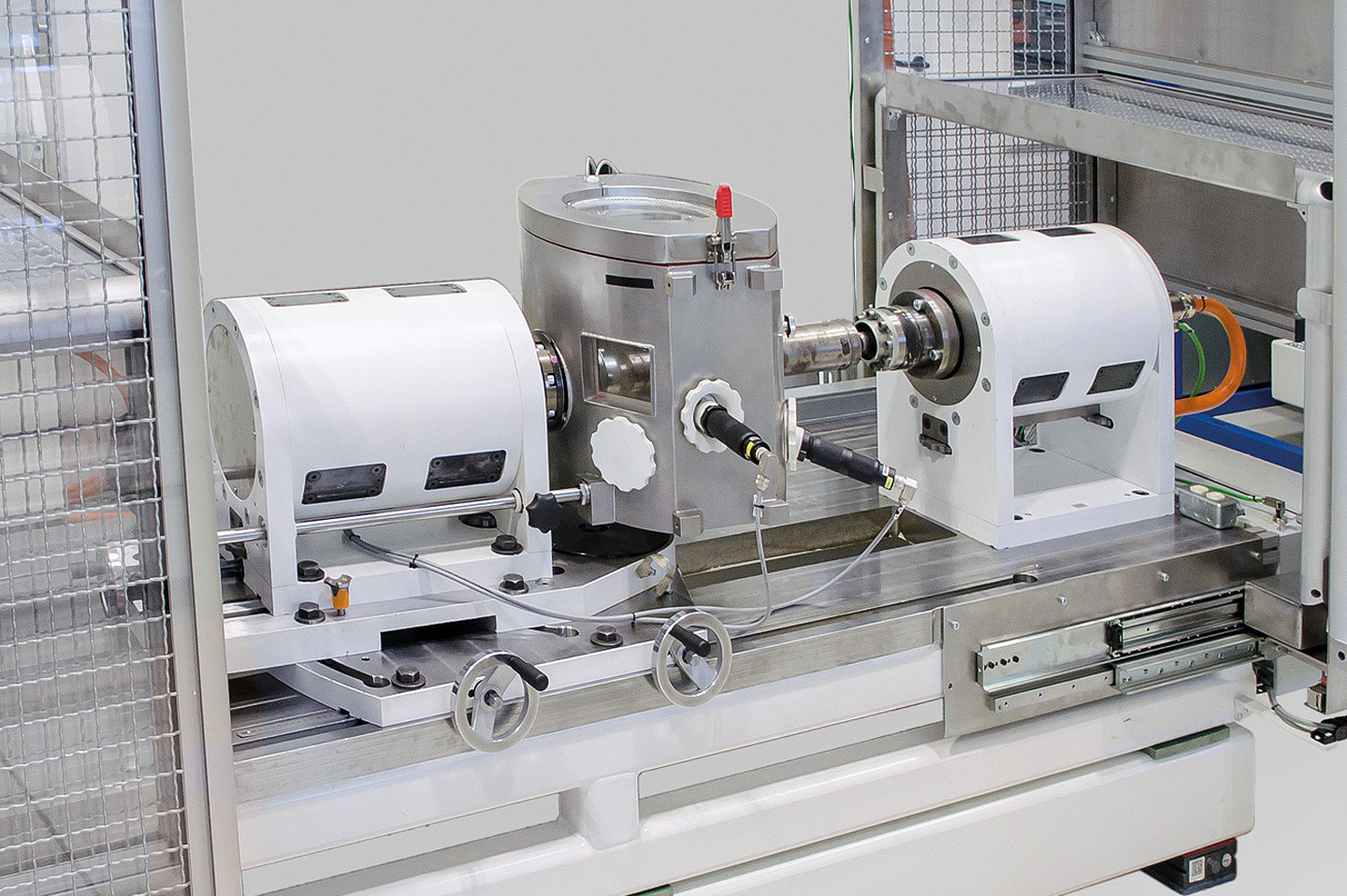

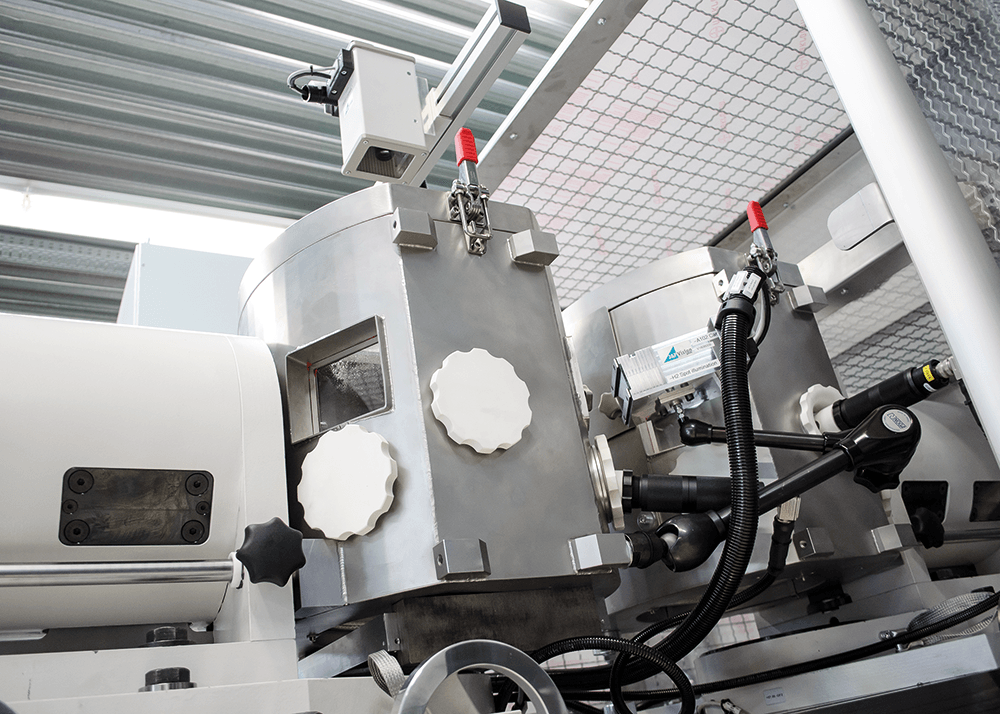

| Motor speed | 0- 12000 rpm |

| Motor power | 25 kW max. 20 Nm at 12000 rpm |

| Articulation angle of drive unit and bearing unit | -5° to 20° |

| Installation dimension from flange to flange | 420 mm- 1250 mm |

| Adjustment range from flange to pivot point respectively | 25 mm- 300 mm |

| Distance between the two pivot points | 370 - 900 mm |

| Temperature range in test cavity | up to 170 °C (short-time up to 200 °C) |

The NovoPS test stand software is a Windows-based solution that is programmed in-house and optimised for the respective test task. As the interface to the user, the uncomplicated user interface provides intuitive access to all functions of the test stand. Moreover, both the connection of the test stand to the customer's conveyor systems as well as its integration into the existing network environment is taken into account. This enables the data acquired to be processed and evaluated independently of the test stand.

Data recording

- Analogue data

- Digital data (SSI etc.)

- CAN data (with synchronisation to analogue data)

Data storage

- Data export as a text file (.csv), DIADEM file

- Database connection ODBC, MS Access, SQL Server

Creating and editing test programs

- Generation or import of test program data records

- Editing program sequences

- Evaluation within the sequences

- Free adaptation of test sequences

- On-line graphic of recorded data