User-friendly measurement and automation software for machining centres for automated quality control of workpieces in individual and series production. It enables maximum productivity and reduces scrap through monitoring measurements between and after machining, statistical process control based on the recorded measured values and reworking in the original clamping set-up.

FormControl X – Production monitoring made easy!

- Highlights

- Features

- Data and more...

With FormControl X, creating complex measuring programmes is self-explanatory, as is automation of machining processes by implementing closed control loops. Measuring results can also be utilised for Industry 4.0 applications.

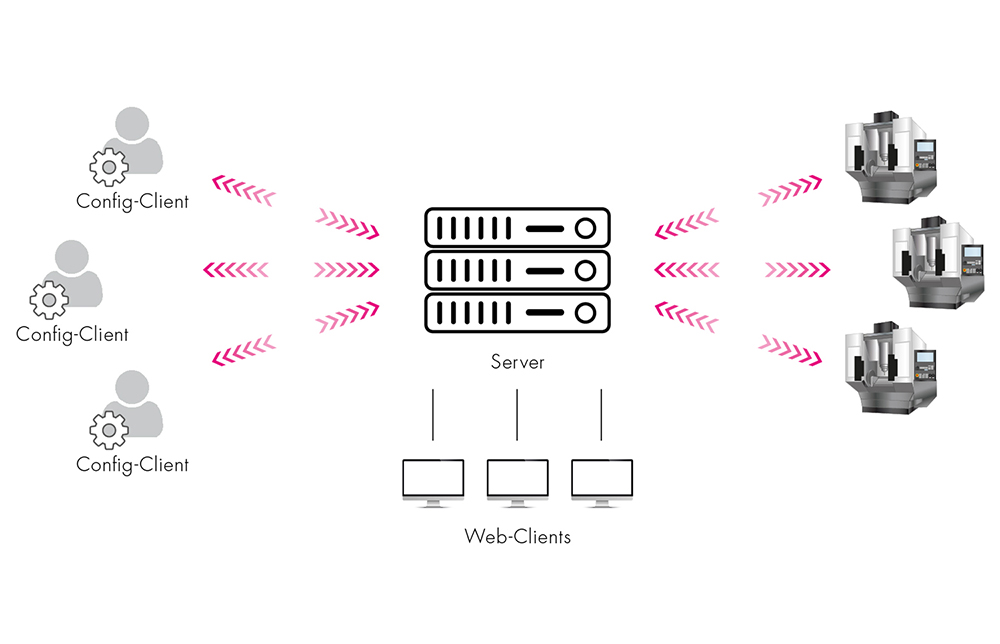

- PC-based solution with modern client-server architecture

- Automation through statistical process control

- Automatic alignment of the workpiece – perfect for automated series production

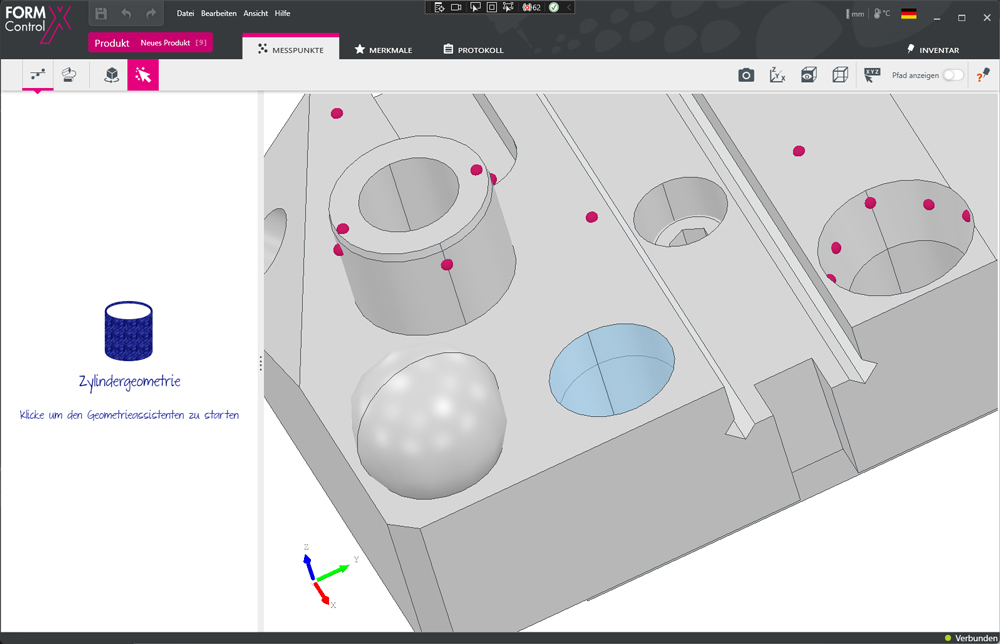

- Simple creation of measuring programmes via context wizard

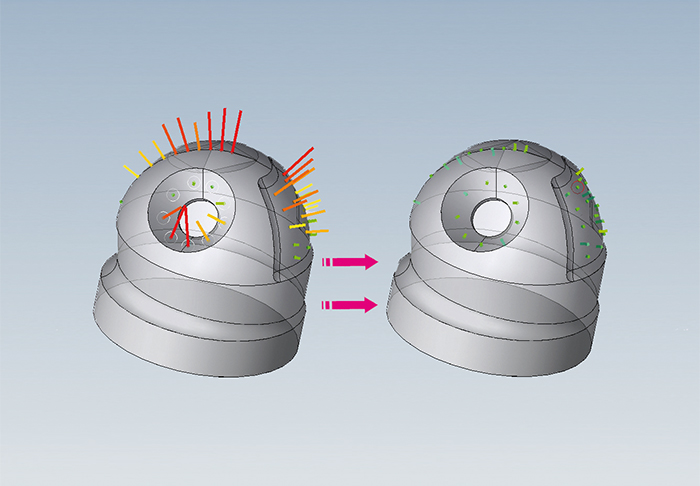

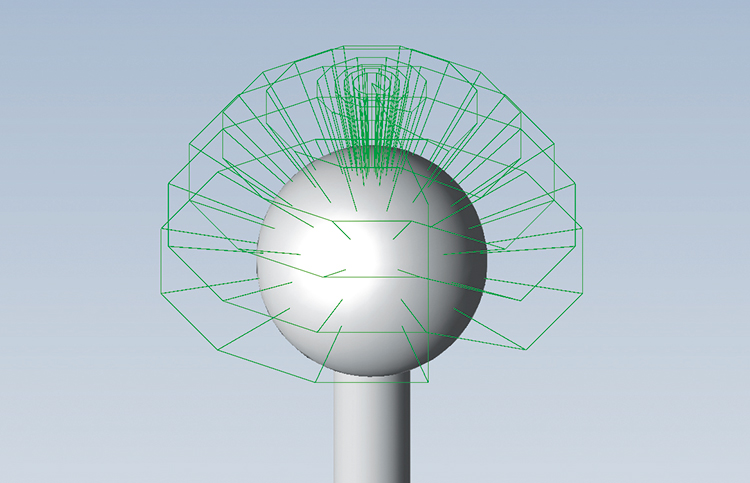

- Automated measurement and evaluation of free-form surfaces and standard geometric elements

- Display of measurement results in a web browser, regardless of end device

- Intelligent measurement path optimisation for shortest measurement times

- Integrated collision control for preventing damage

- Output of measurement protocols as a document as well as in CSV and JSON format

- Logging and documentation of final quality

- Automation of processes through tool-specific determination of correction values

- Definition of warning and intervention limits

- Measurement results serve as correction value and basis for optimisation

- Alarm output to the operator or automatic rejection of NOK parts

- Automatic compensation of tool wear

- Assignment of measurement results and component is done by means of a unique ID

- Implementation of low-manpower, highly productive machining processes

- Continuous documentation of final quality

- Automatic adaptation of the reference points of the machining program to the actual position of the workpiece

- Enables automated machining of parts with small allowances

- Simple re-setting through automatic correction of the workpiece position in up to 5 machine axes

- Axis locking for application-specific alignment

- Fast rework due to elimination of time-consuming, manual alignment

- No scrap resulting from the machining of badly aligned workpieces

FormControl X is very easy and intuitive. Even complex projects can be configured and executed quickly. Jobs are created conveniently at the click of a mouse, and the context wizard in the CAD model automatically recognises geometry areas and suggests typical measuring points, evaluations or standard tolerances.

- Modern client-server architecture: all data of the defined jobs and measuring devices can be used across different machines

- Intelligent measurement path optimisation: FormControl X calculates the fastest possible measuring sequence for each job, meaning that the measuring time can be kept as short as possible

- FormControl X works on the basis of a modern client-server-architecture

- The measurement processes (jobs) are defined via the Config-Client on the PC and transferred from the server to the machines

- For evaluation, the recorded measured values are retrieved from the server and visualised via the web browsers of any end devices

The foundation of intelligent automation solutions is process data that is evaluated live or very quickly and serves as a control variable for optimising the process. FormControl X is designed precisely for this purpose and adjusts based on the recorded measurement data so that the machining process always remains within the predefined limits.

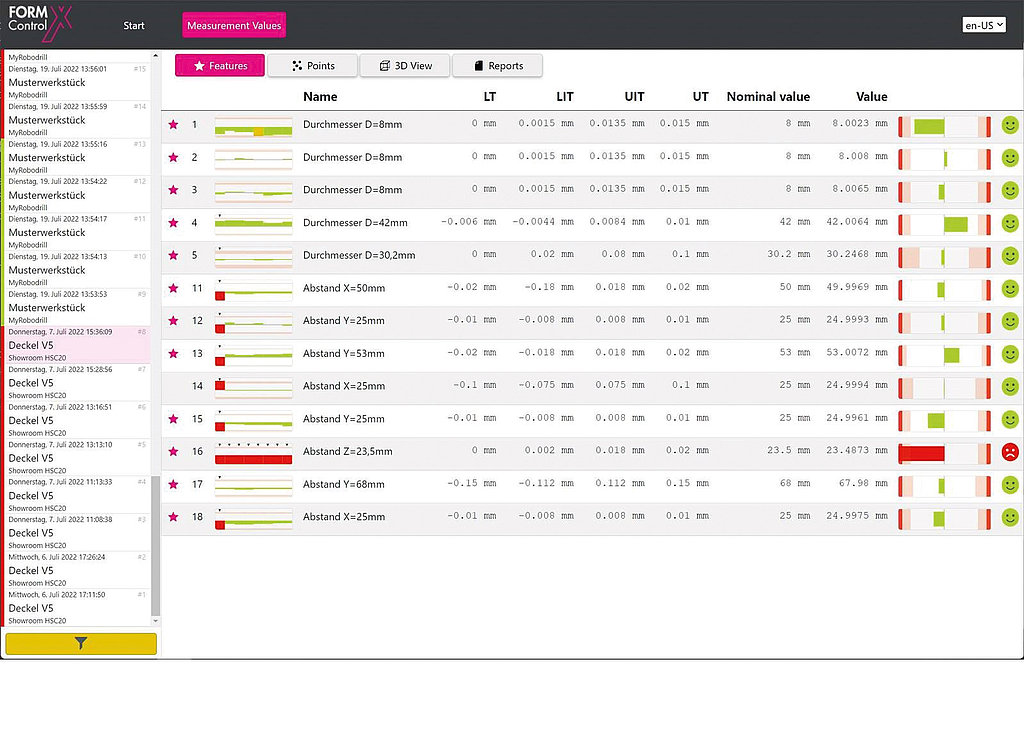

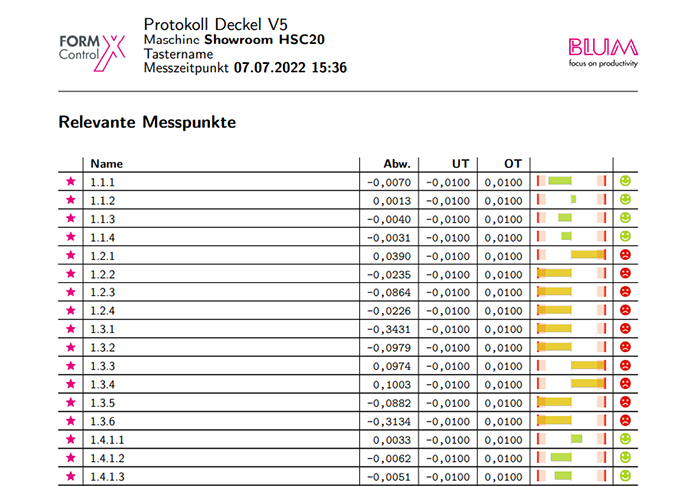

- Graphical processing of measurement results for visualisation in a web browser

- Creation and evaluation of data series over a long period of time

- Output of measurement protocols as a document as well as in CSV and JSON format

- Display of measurement data with deviations from programmed/actual values

- Colour coding of deviations from tolerance limits

- Symbolic representation of the measured value status for easy visualisation of over-/undersized dimensions

- Use of recorded measurement data for the evaluation and optimisation of machines and tools used

- Individual adaptation of the measurement protocols