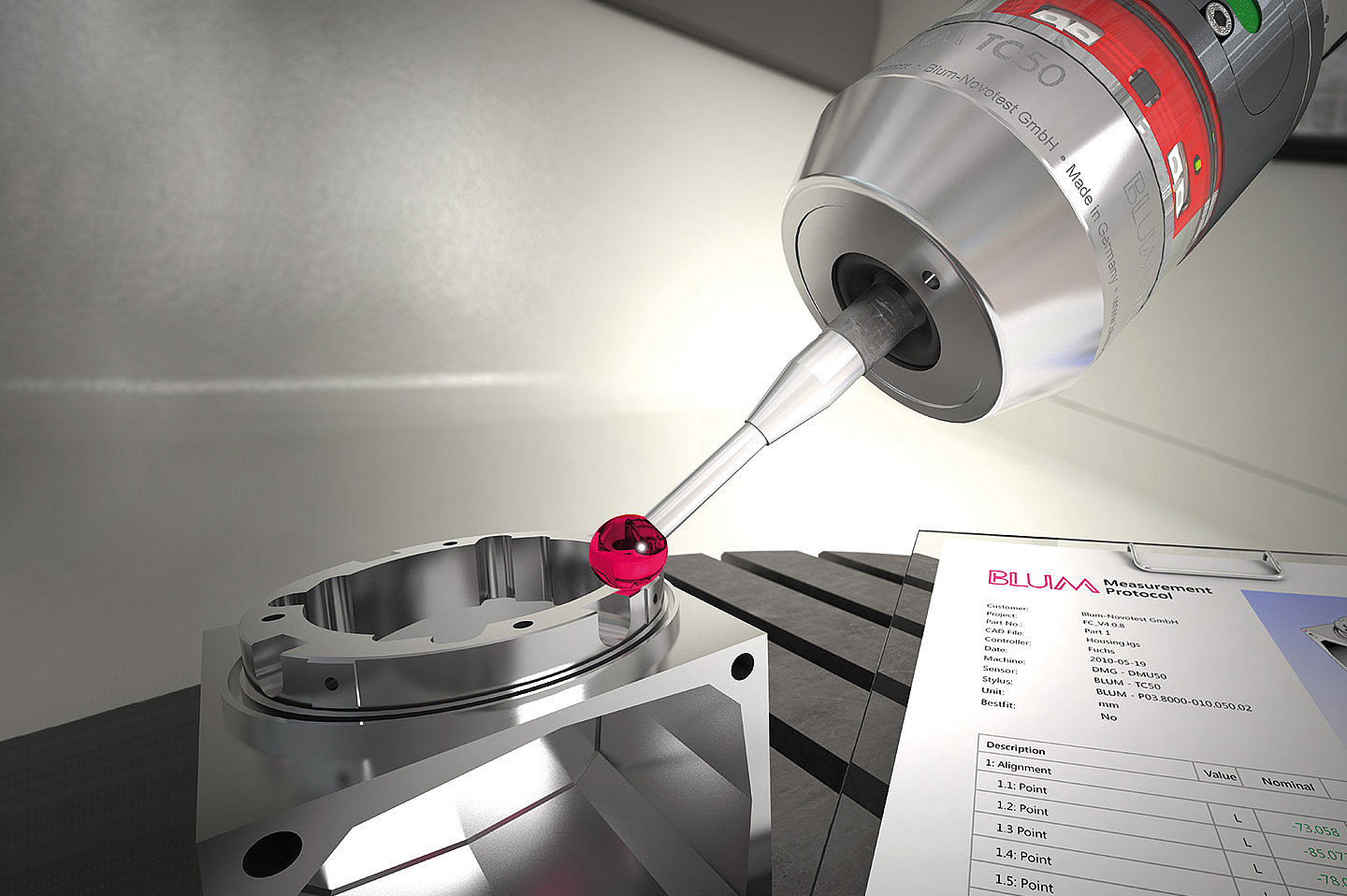

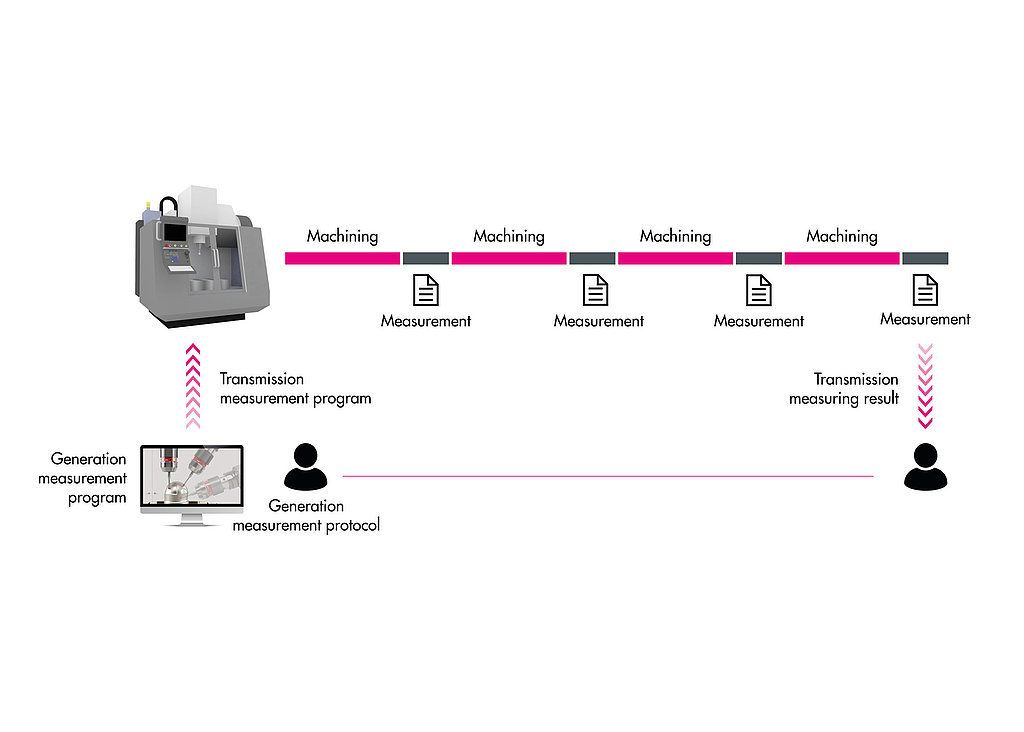

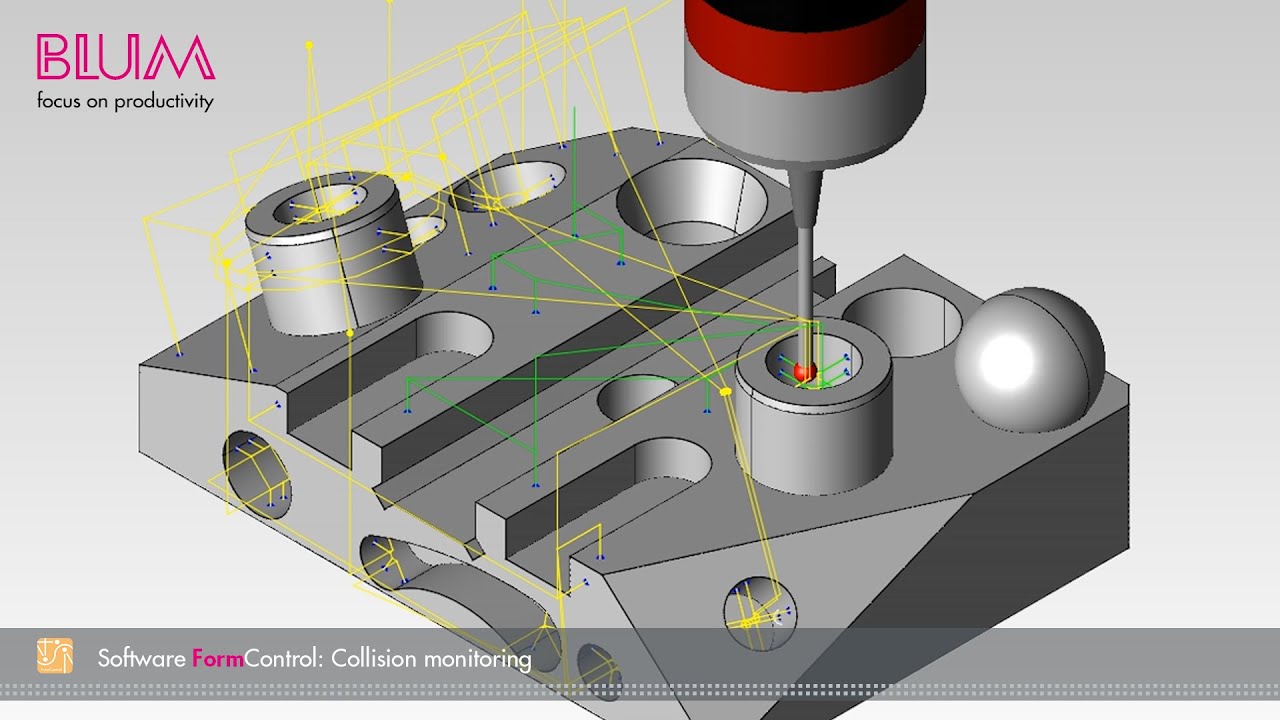

User-friendly software for rapid quality control of contour measurement and standard geometric elements in CNC machining centres. Maximum productivity as well as reduced rejects thanks to control measurements between the machining steps and rework in the original setting.

FormControl measurement software – Measuring at the click of a mouse in CNC milling machines

- Highlights

- Applications

- Features

- Options

3D measurement software for machining centres

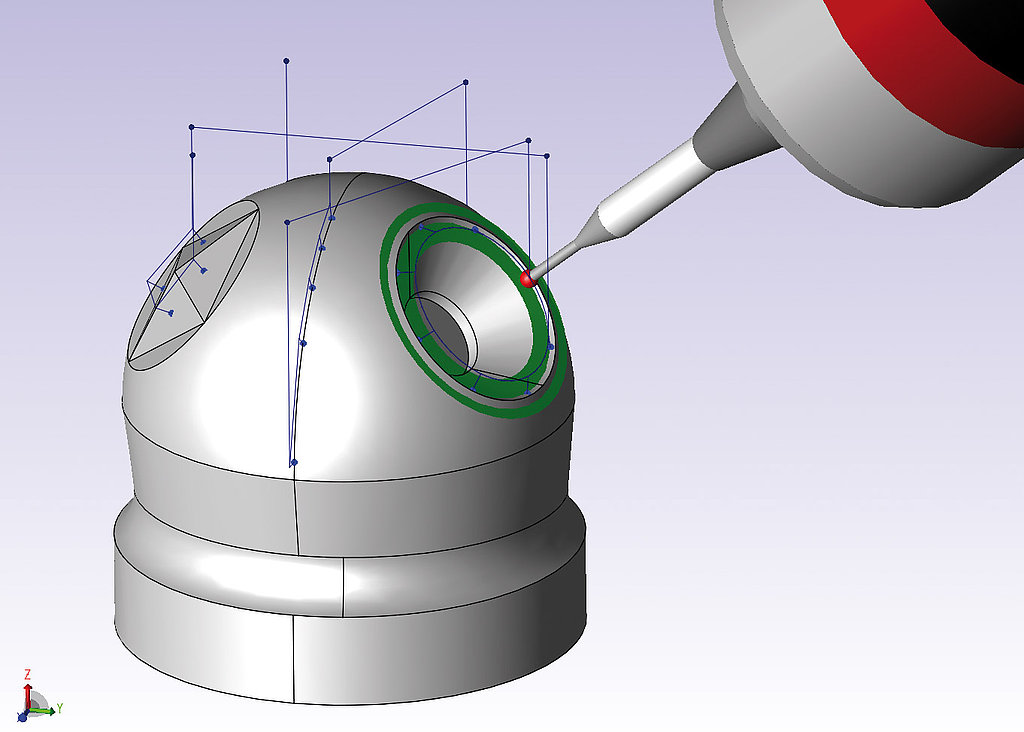

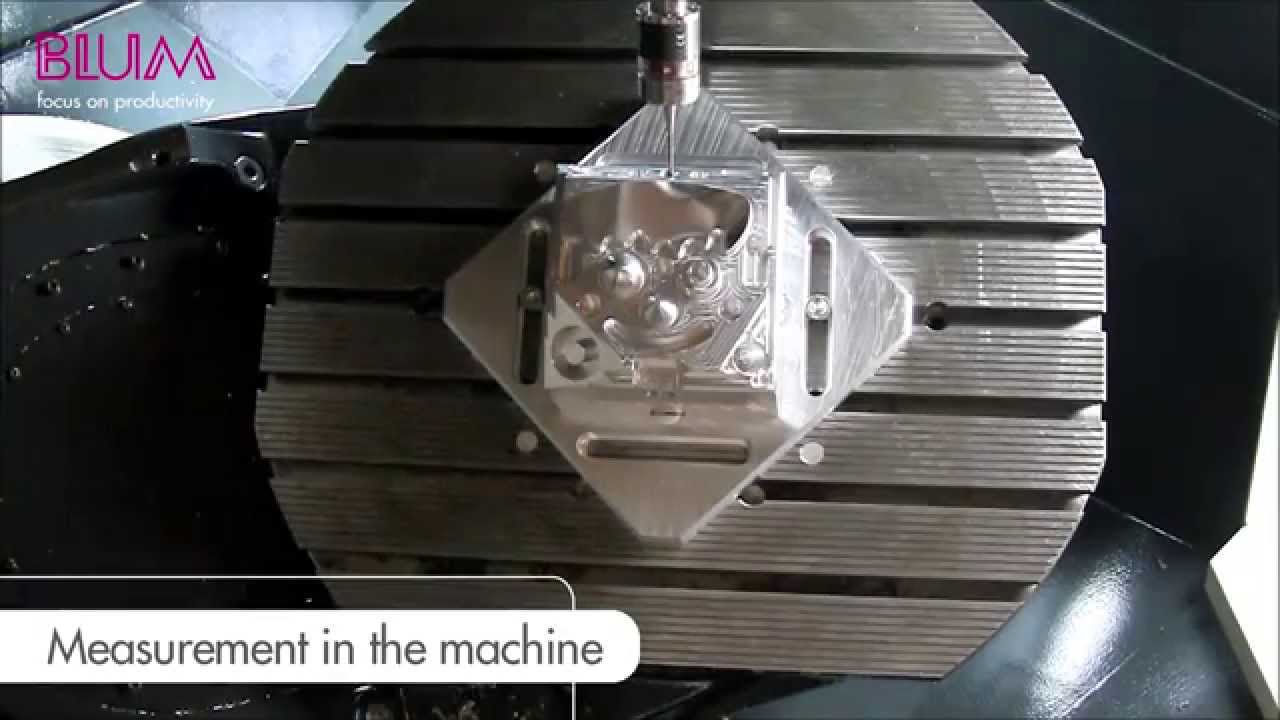

FormControl measurement software by BLUM can measure complex workpieces in the machining clamping. Wait times, a transport for measuring machine and associated problems during resetting are therefore a thing of the past.

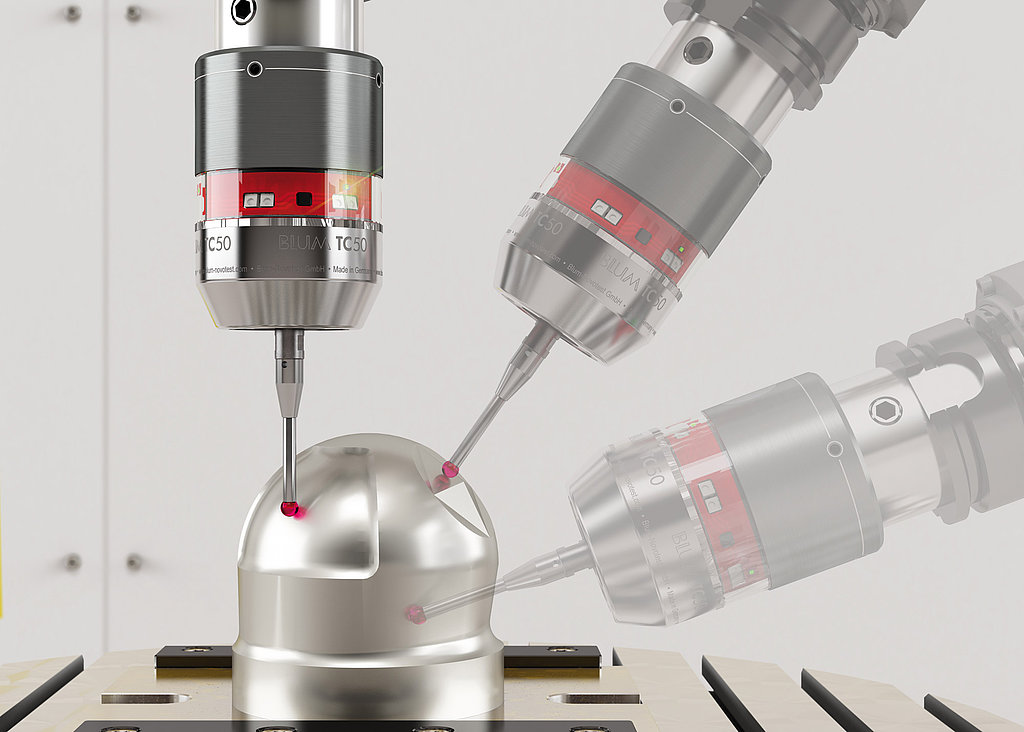

Precise determination and mathematical correction of the current workpiece position and alignment after resetting.

Fast and flexible measurement of standard geometric elements: bore & pins, spheres, cones, outside & inside width, radius, step. Measurement of clearances, single points, angles, inside and outside diameters, inside widths and outside widths.

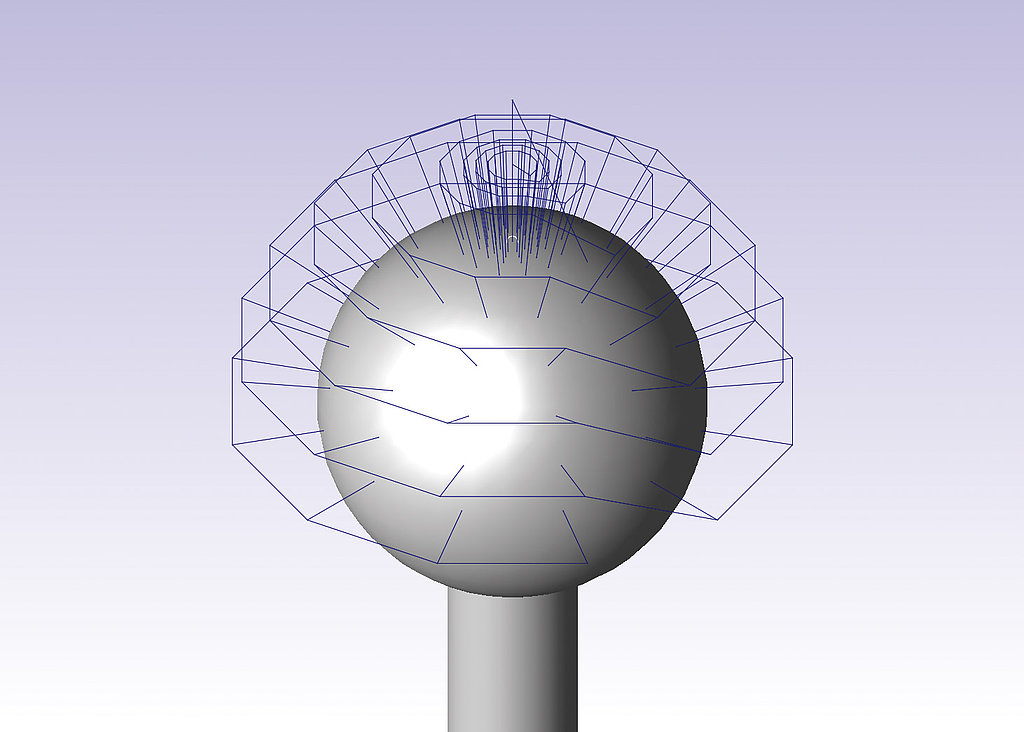

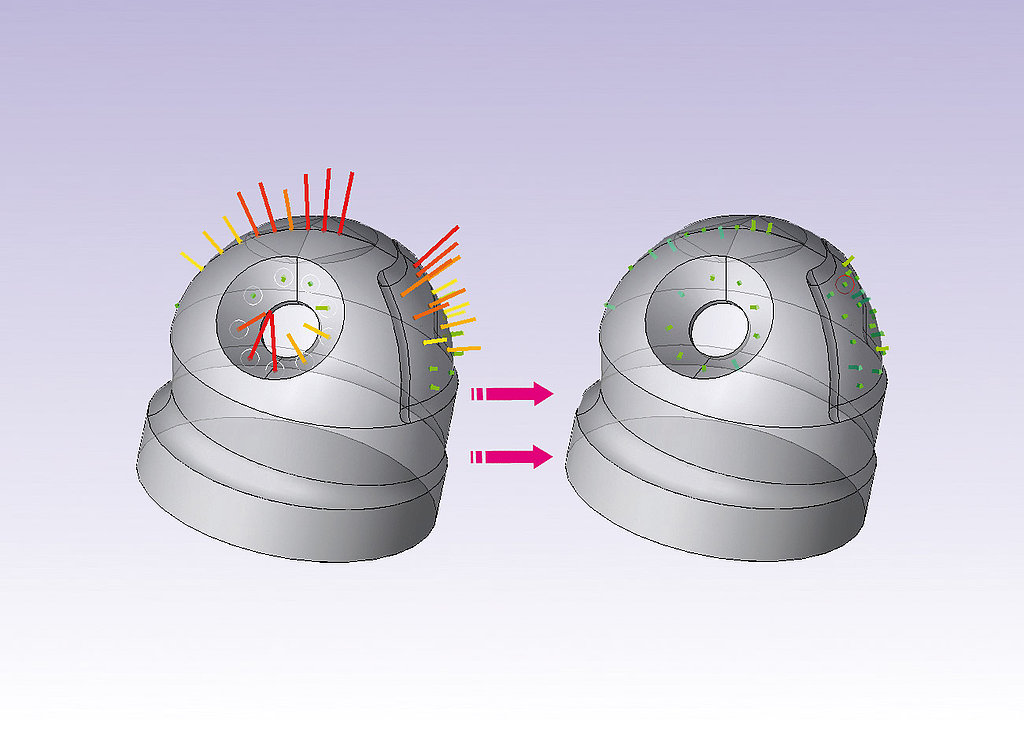

High-precision measurement of complex contours and recording the deviation from the CAD model.

Inspection of the manufactured workpieces for machining errors and adherence to manufacturing tolerance by means of control measurements prior to clamping.

The FormControl measurement software was developed primarily for creating complex measurement projects on machining centres in mould and die applications. It is ideally suited to the measurement of one-off as well as mass-produced workpieces.

Compensation of the temperature-dependent thermal behaviour of machining centres.

- Orientates the workpiece mathematically in space to create the best possible match of measuring points using the CAD model

- Continue machining with optimised positioning

- Compensates systematic measuring errors

- Individual weighting of measuring points

- Workpiece can be displaced and rotated at will

- Axis locking for application-specific alignment

- Determination of actual workpiece position and return for CNC control

- Automatic correction of workpiece position (displacement, torsion, tilting) in up to 5 machine axes

- Fast rework due to elimination of time-consuming, manual alignment

- Ultra-high precision due to optimised alignment after (re) setting

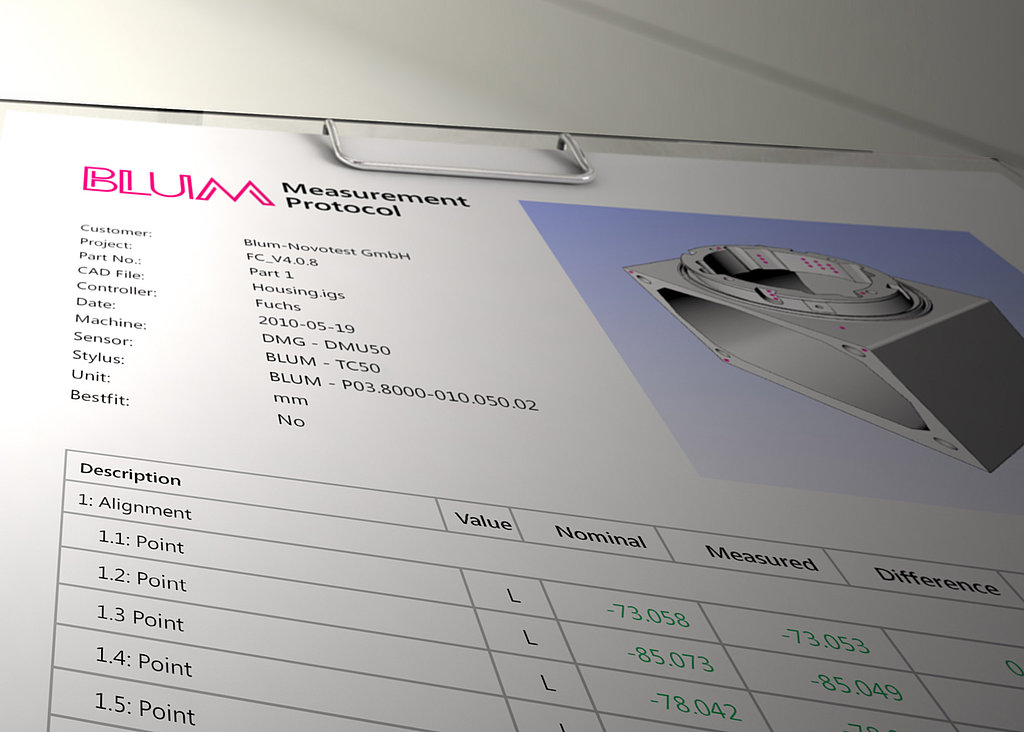

- Automatic execution and logging of measurement jobs in-between and after machining

- Easy assignment of measurement job and component due to unique ID

- Fast creation of a large number of measurement protocols

- Implementation of minimally manned, highly productive cutting processes in tool and mould making and in the aerospace industry

Applications

A big benefit of the software is that we are able to measure our workpieces in their original clamp fixtures in the machining centre. That saves us a lot of time, because we can do any necessary reworking immediately.