- Highlights

- Your benefit

- Fast configuration of customized test sequences by excellent software solution

- Return on invest through reduction of field service by pre-assurance of product quality

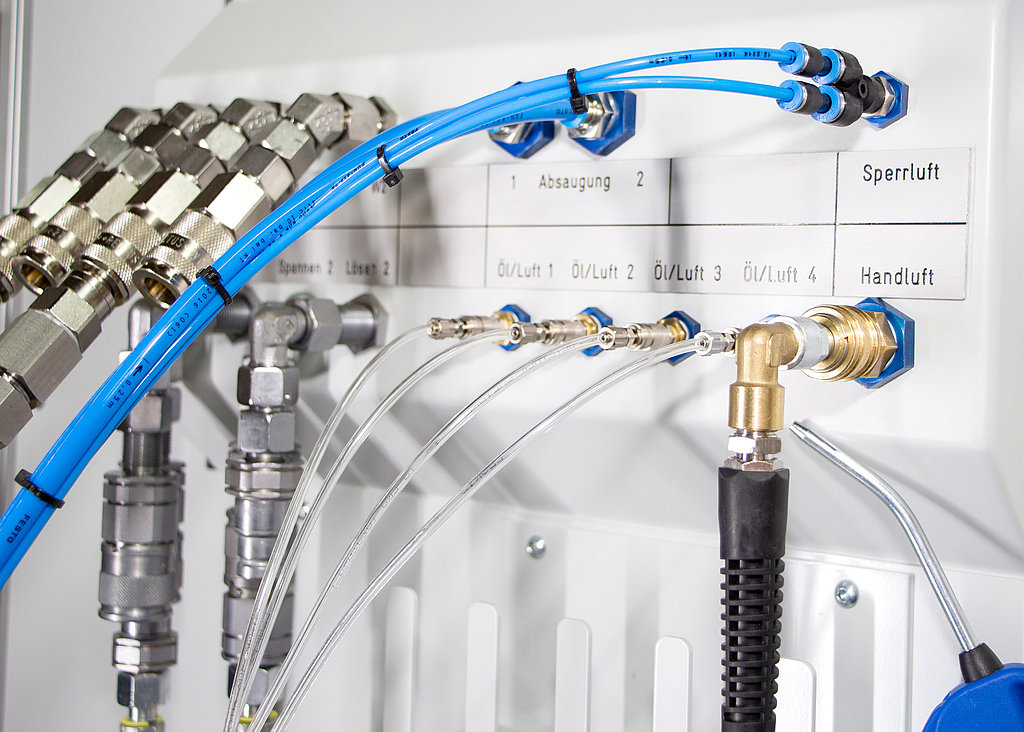

- Ready-to-install motor spindle because of bearing run in procedure part of the testing

- Various test sequences like reverse rotation procedure, maximum speed test, …

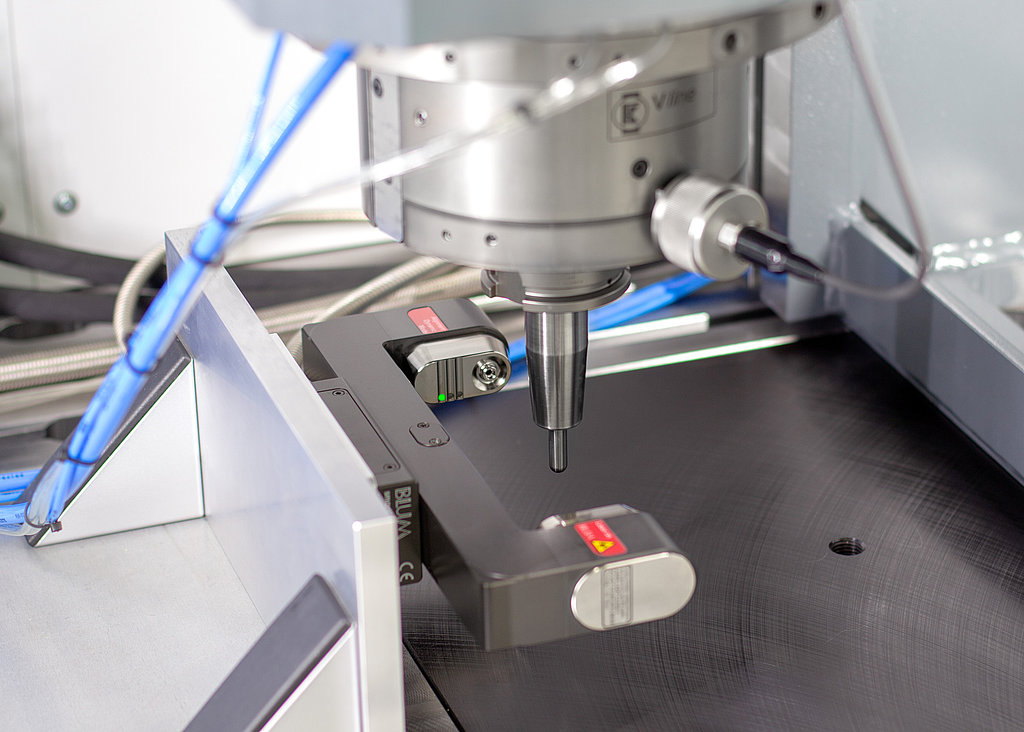

- Connection possibility of spindle internal and external sensors

- Identical reproduceable test sequences for different service locations

- Automated test sequence and data acquisition without any influence by operators

- Flexible and universal application for different type of motor spindles

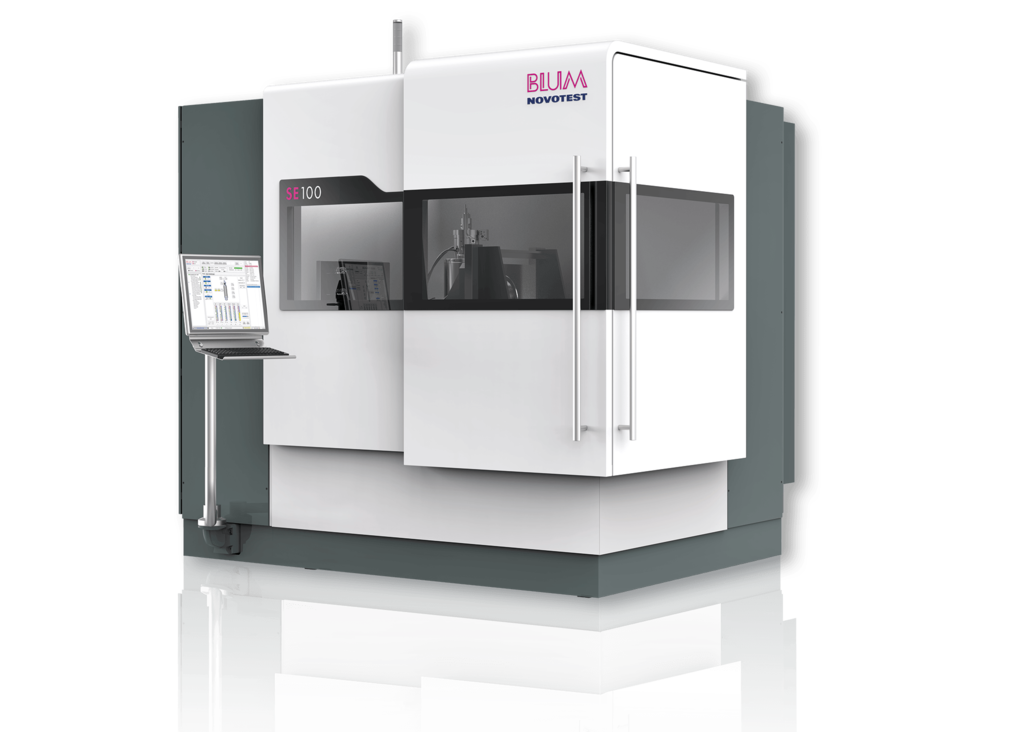

- Small footprint by compact design for easy transportation and quick loading/unloading of spindles from above

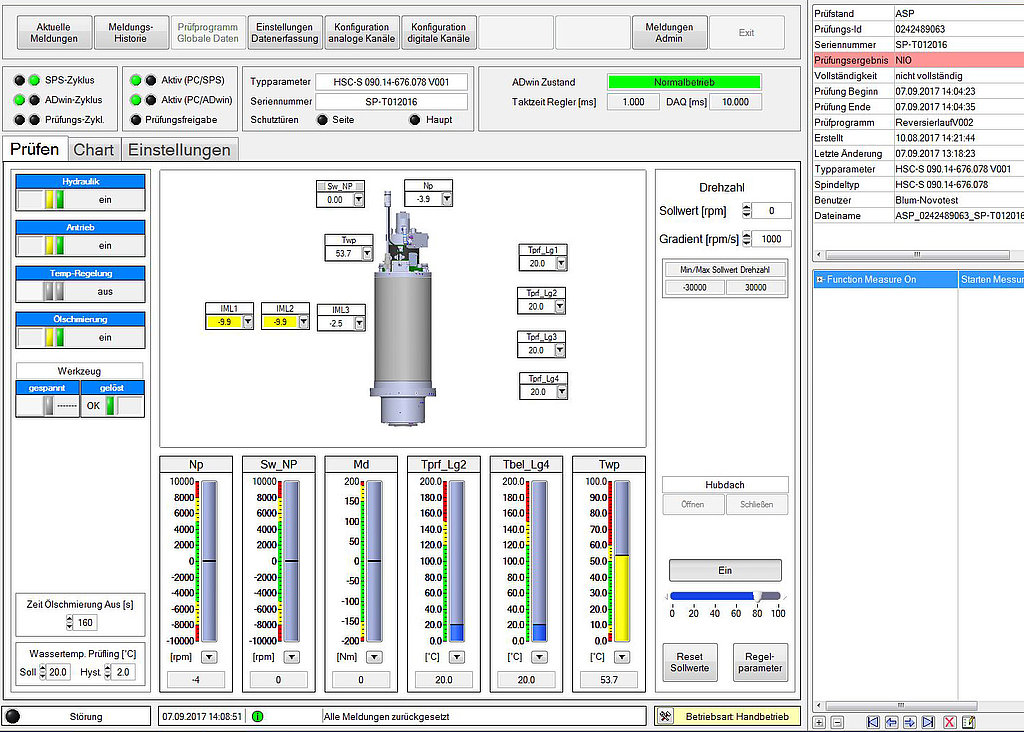

The test-stand software for spindle test stands is a Windows-based solution that is programmed in-house and optimised for the respective test task. As the interface to the user, the user interface provides intuitive access to all functions of the test stand.

Test sequence

- Fast configuration of customized test sequences

- Intuitive creation of complete applications using software modules

- Global networking of the test benches possible

Data recording

- Manual and automatic data collection

- Real-time display of measured analog data

- Test results in .xml file

Spindle ID

- Documentation of the delivery/arrival condition

- Findings for optimization/development

- Preventive maintenance through data collection possible