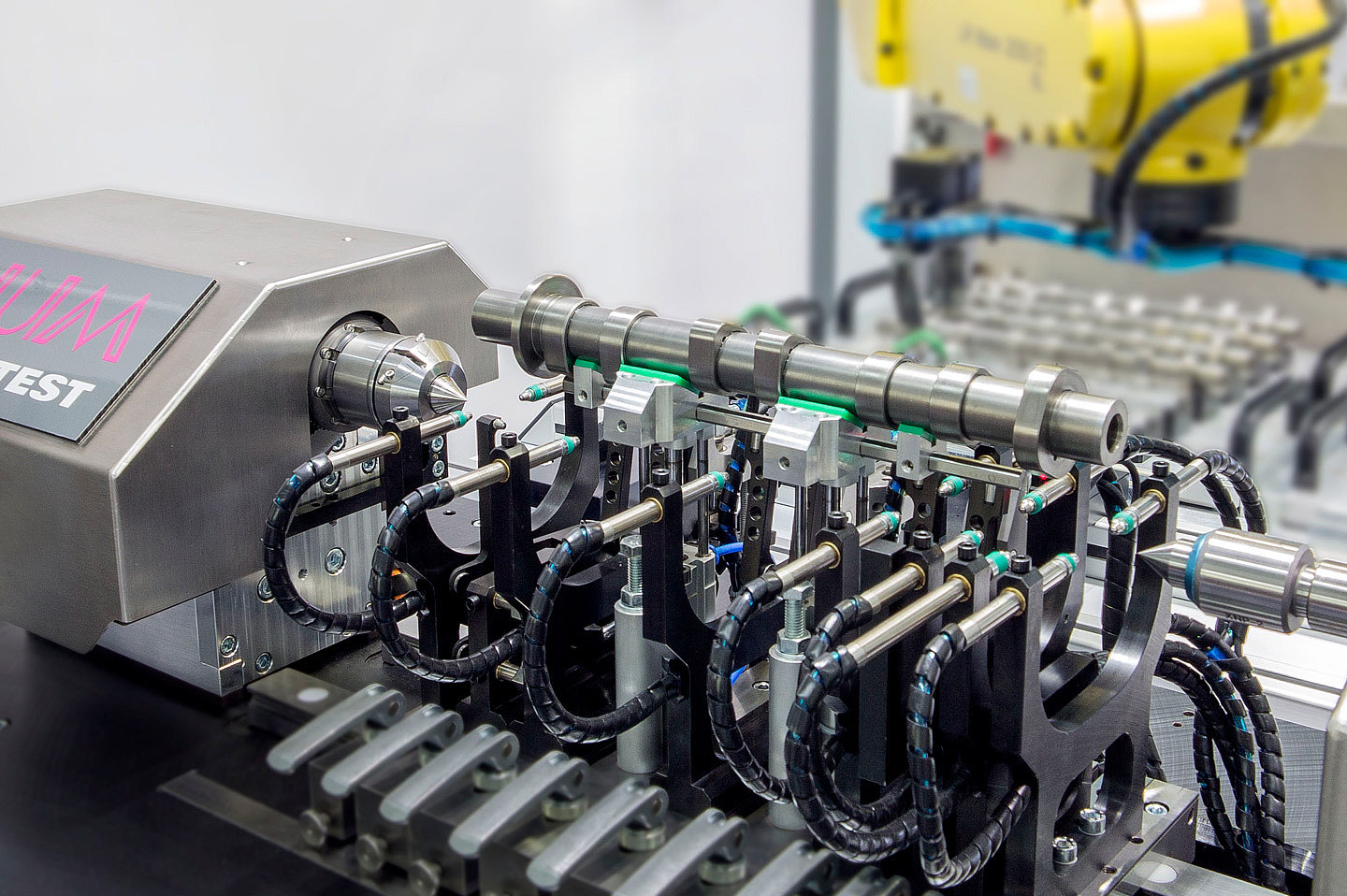

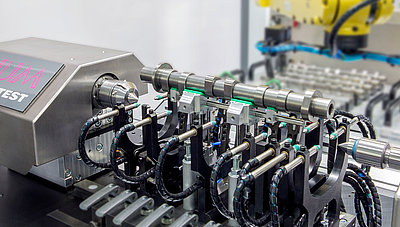

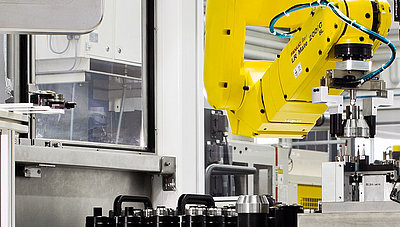

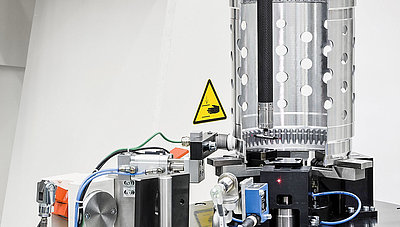

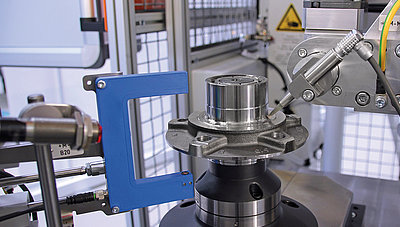

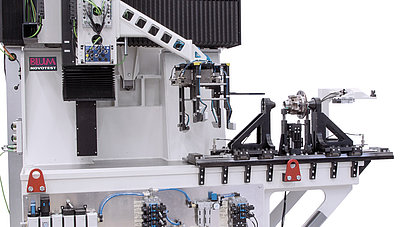

The specialist area of the measuring machines business division includes dimensional, geometry and crack testing primarily on rotationally symmetric components. Using tactile, non-contact as well as combined procedures, the service spectrum ranges from integrated post-process solutions to static and dynamic measurement and all the way to autonomous systems. Optional supplementary testing is possible, for example, for cracks, hardness or natural frequency.

Measuring machines for mass production

Here, you can find the latest measuring machines for a large number of components.

Process optimisation and extensions

In addition to component geometry checks, the broad service offering includes active process optimisation based on the provision of correction values in the quality control loop. This is rounded out by a range of extension modules for classification, sorting, workpiece identification, etc.

Why use measuring machines by Blum-Novotest?

- No sacrifices in productivity during simultaneous measurements during prime time

- Comprehensive knowledge from machining to the testing of finished parts

- Increase in-process reliability

- Realise continuous process chains

- Minimise rejects

- Ensure unmanned 24/7 manufacturing

- Increase efficiency and reduce throughput times

- Maintain and increase competitiveness

- Worldwide sales and service provided by company subsidiaries