- Highlights

- Your benefit

- Variants

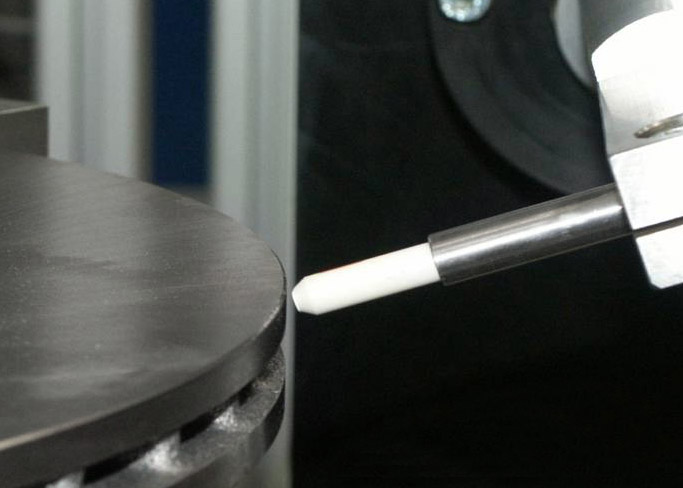

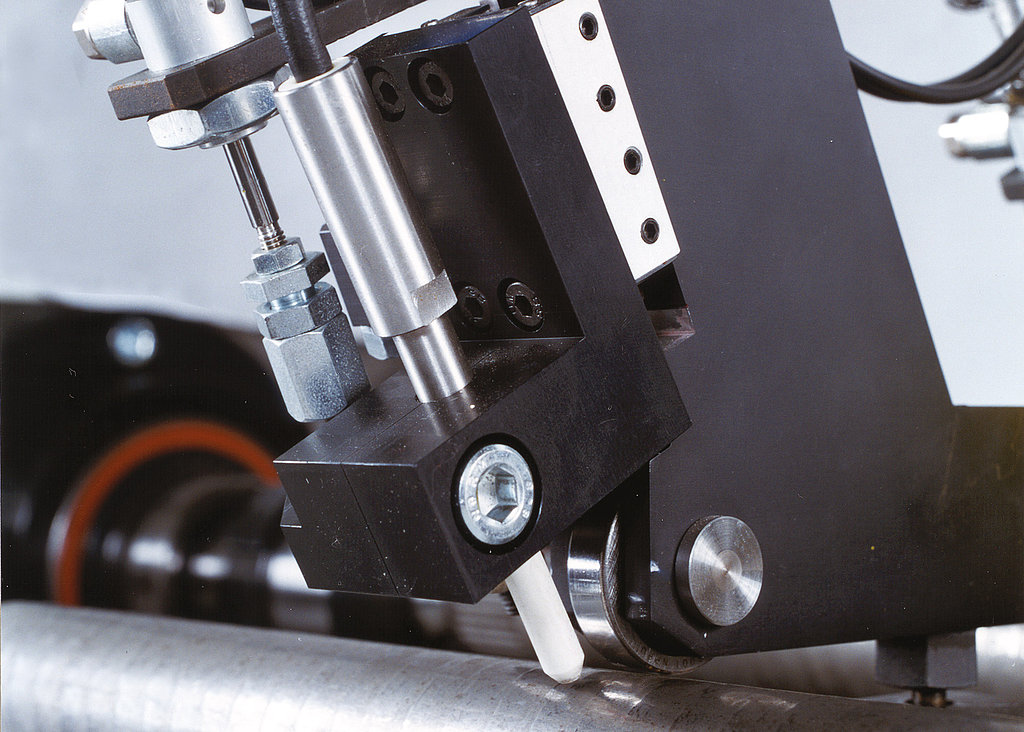

- Eco-friendly, fast and fully-automated objective inspection

- Reliable identification and discharging of cracked parts

- High availability thanks to extremely solid and durable design

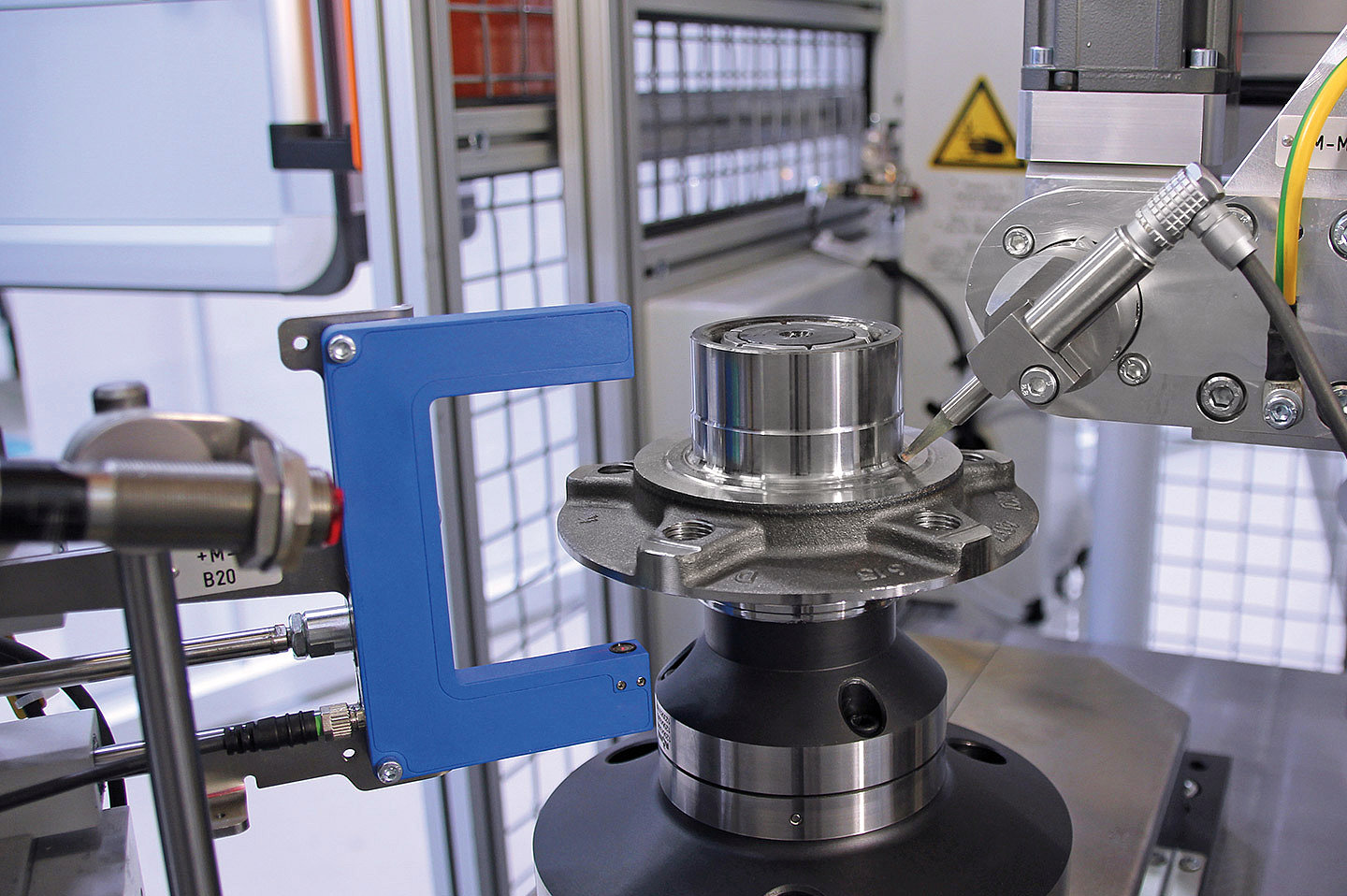

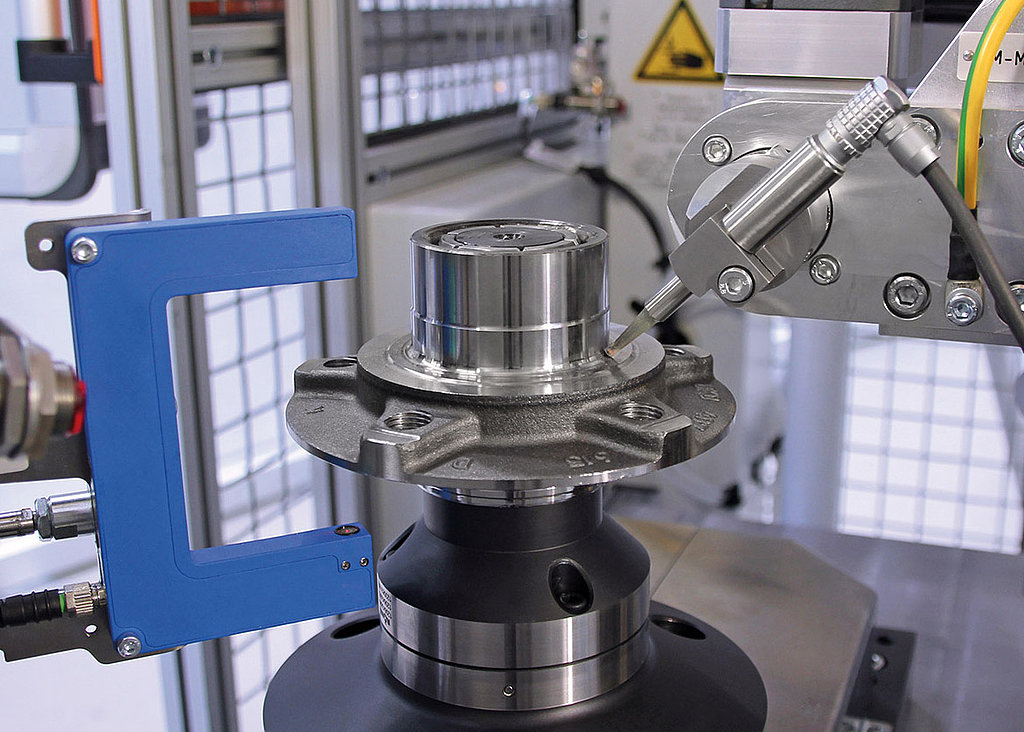

- Can be fully integrated into the production line

- Automation by means of inter-linkage, conveyor, shuttle, robot or gantry

- Can be individually extended to accommodate additional test criteria such as shrinkage cavities, pores, etc.

- Marking system for OK/NOK identification or individual coding

- Typically arrange immediately downstream of the machining station, often combined with a multipoint measuring machine

- Also available as measuring system for external control

Crack detection testing machine for wheel hubs